Why you can't afford an unreliable valve

Choosing the right rotary valve can improve your productivity. Choosing the wrong one can do the opposite.

0:04

Hi and thanks for joining us for our webinar on why you can't afford a cheap rotary valve. At ACS Valves, we know that valves are not commodities and we're committed to spreading this message because it seems like our industry is still struggling with debunking this myth. The truth is that we and other rotary valve manufacturers invest a great deal of time researching and understanding our customers' businesses, their specific lines, and how to move bulk material in the most efficient and reliable way possible within their context.

0:34

In fact, we have a line of 23 rotary valves and counting because the valve you use does make a difference. Of course, price will always be one of those things that some companies have to prioritize above all, and we understand that. For those companies, we want to make a case for why buying cheaper isn't actually cheaper in the long run. Without further ado, here it is.

0:55

Number one, more downtime. Sure, you got a great deal, but you have to ask yourself why. How was it built and with what materials? How much was your particular process factored into designing the valve? These are important questions because they have measurable results once the valve is in production. If it's built poorly, it will likely break down, require more than average maintenance, and leak material. The downtime it takes to deal with any one of these situations accumulates, and you know better than anyone that at an average rate of $500.00 per hour, downtime is costly.

1:30

Number two, shorter life cycles. Let's talk about how long valves are supposed to last. If you're getting less than one year of production from your valve, you're paying much more in replacement costs over time, and even before the point of purchasing a new valve, you're often buying spare parts in the meantime just so your valve can function a little longer. Again, these costs accumulate.

1:49

Three, extra costs for safety. I don't think we're alone in thinking that safety in manufacturing is not just important, it's necessary. And yet there are so many substandard valve manufacturers that do not include NFPA or OSHA compliant features in their valves. Instead, compliance is sold as an afterthought feature and customers have to pay extra for it.

2:10

Four, increased risk of contamination. Cheaply made, bolted together valves have cracks and crevices where contaminants and bulk material are likely to build up. Depending on your industry, this kind of situation can be extremely dangerous. If bacteria are found or if cross contamination occurs after material changeover, it's grounds for a recall, a costly nightmare for any brand. To prevent this scenario, companies have to spend extra time cleaning these crevices in the valve housing, which again costs more in downtime.

2:40

Five, lack of scalability. The industry standard pressure rating is 7 PSI, and that's great... until your business wants to increase production rates. With a cheap valve, chances are there's no built-in scalability. This means if you need a 10 PSI rating, you'll have to purchase a brand new valve.

2:57

Number six, bad service. You can't put a price on good service, but with frequent phone calls, refusal to repair or troubleshoot faulty equipment, and delays in responding to complaints, you can definitely put a price on bad service.

3:13

Number seven, missed opportunities. Ideally, you want a rotary valve that does more than just work. Ideally, you want optimal performance that gains efficiencies for your line, such as reduced energy consumption, features for faster cleaning, design for effective material release and zero dead zones.

Metering consistency, coatings for reduced wear and longer life cycle, shaft seals that don't have to be adjusted. With a cheaper valve, chances are you are missing these opportunities. And it's not just that you're losing money, it's that you're failing to make more money when you could be.

3:43

Simply put, a cheaply made valve not only means paying more, it means getting less. Less efficiency, less performance, and much less ROI.

3:52

Now that we've given reasons why cheap, bolted together equipment is unreliable and ultimately more costly, we don't want to leave you hanging. So we've made a short list of questions that you can ask your supplier during the buying process to help you ensure you're getting the most efficient high performance valve for your line.

4:07

Number one: Where and how is the valve made? Make sure you're getting quality materials, preferably local, that are cast and not pieced together. You want a durable piece of equipment that will last as long as possible. Number two: Does it meet industry safety standards? We wish you didn't have to ask this, but from our experience, you should. Safety compliant features should come as standard, not extra. Number three: How will this valve optimize my specific process? The answer will vary according to your application, but whatever it is, the answer should demonstrate a knowledge of your priorities and your process. Whether it's quick-clean features or coatings for abrasion resistance, your supplier should be able to walk you through the equipment's features and benefits beyond just saying, "This is really good for feeding." Number four, what happens if it breaks down or fails? Get a sense of what kind of support waits for you if you need it. Your supplier should stand behind their products, eager to help when needed. Number five: How much? Hey, we never said that price wasn't important. Your suppliers should be able to offer a competitive price for the value they bring.

5:09

Before we wrap up, we want to add one more thing. A lot of people think they're stuck with their existing valve manufacturer because their valves were built to a certain size or to accommodate certain equipment. This is not the case, at least not with us. It is absolutely possible to build a custom valve to pre-existing size specifications. We do it all the time. So no, you are not stuck with your old valve. Thanks for joining us today for our webinar on why you can't afford a cheap valve. If you have any questions, please do call us or e-mail us. Thank you and take care.

More Videos

-

![How shear pin sprockets prevent damage to your valve]() How shear pin sprockets prevent damage to your valve

How shear pin sprockets prevent damage to your valveWatch the video to see how shear pin sprockets can help you avoid unnecessary downtime and parts replacements.

-

![Why is rotor maintenance so important?]() Why is rotor maintenance so important?

Why is rotor maintenance so important?Rotor tips wear down over time, causing issues with material flow. Our video illustrates why rotor maintenance is so critical to the overall efficiency of your rotary airlock valve.

-

![See the Multi-Port Valve at work in 3D]() See the Multi-Port Valve at work in 3D

See the Multi-Port Valve at work in 3DLearn about the features of our Multi-Port rotary airlock valve as it conveys high volumes of material in different conveying scenarios: one line, split feeds, and varying types of equipment.

-

![Steps to Clean Your Quick-Clean Rotary Valve]() Steps to Clean Your Quick-Clean Rotary Valve

Steps to Clean Your Quick-Clean Rotary ValveCleaning a Quick-Clean rotary valve is simple! This animation offers a step by step instruction on how to do it.

-

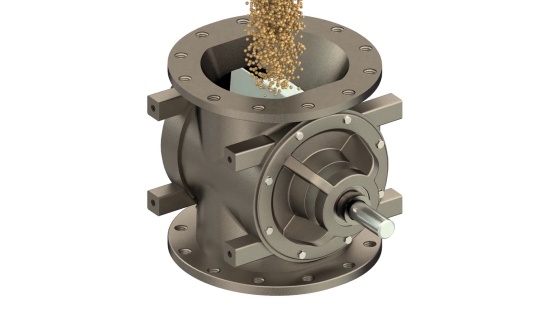

![A 3D view of material flow in an MD Series rotary airlock valve]() A 3D view of material flow in an MD Series rotary airlock valve

A 3D view of material flow in an MD Series rotary airlock valveWatch a quick 3D demonstration of material flow and pocket fill in an MD series rotary airlock valve. The video is silent.

-

![Drive Side Endplate Removal for ACST-4 Seals]() Drive Side Endplate Removal for ACST-4 Seals

Drive Side Endplate Removal for ACST-4 SealsNeed a guide to removing the drive side endplate on your ACST-4 seals? Watch a quick visual breakdown of the process. The video is silent.

-

![ACS Valves: It Will Fit]() ACS Valves: It Will Fit

ACS Valves: It Will FitOur valves will fit literally anywhere. Watch the video to find your industry.

-

![Rotor Assembly Tolerance Check]() Rotor Assembly Tolerance Check

Rotor Assembly Tolerance CheckKeep valves compliant by ensuring rotor-to-housing clearance stays below 0.0079.

-

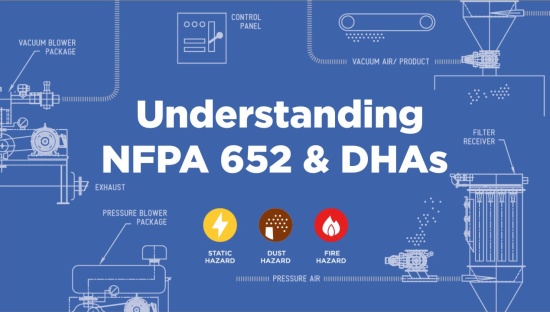

![What you need to know about DHAs and NFPA 652]() What you need to know about DHAs and NFPA 652

What you need to know about DHAs and NFPA 652Every material is different, so every valve has to be designed to handle each combustible dust in order to prevent deflagration.

-

![Will it clean?]() Will it clean?

Will it clean?We talk a lot about how easy it is to clean our valves. Watch as we put our dinner into one of our valves and then clean it up!

-

![Yes, you have to remove our endplates to replace the shaft seal]() Yes, you have to remove our endplates to replace the shaft seal

Yes, you have to remove our endplates to replace the shaft sealWe're facing our critics head on.

-

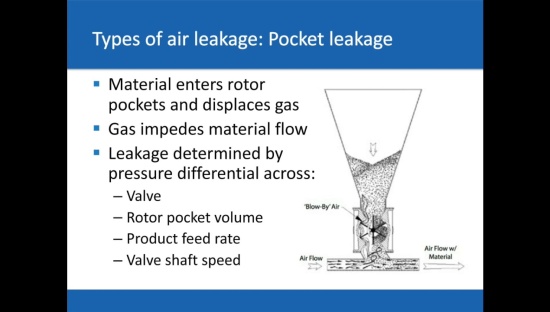

![Understanding Airlocks: The key to increasing ROI]() Understanding Airlocks: The key to increasing ROI

Understanding Airlocks: The key to increasing ROILearn the fundamentals of airlock performance, how to minimize air leakage and how improve efficiency.

-

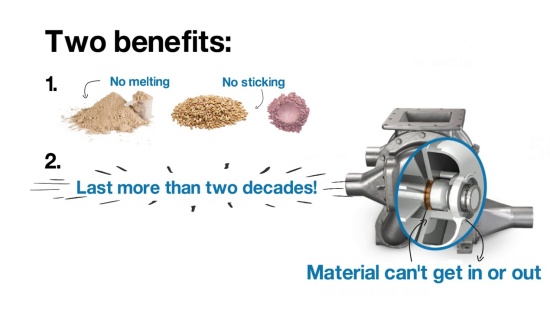

![How to convey sticky material with a blow-through]() How to convey sticky material with a blow-through

How to convey sticky material with a blow-throughWhen conveying sticky material, you can get the benefits of a blow-through without the premature wear.

-

![Why you can't afford an unreliable valve]() Why you can't afford an unreliable valve

Why you can't afford an unreliable valveChoosing the right rotary valve can improve your productivity. Choosing the wrong one can do the opposite.

-

![Make cleaning suck less with our Quick-Clean valve on RotorRails™]() Make cleaning suck less with our Quick-Clean valve on RotorRails™

Make cleaning suck less with our Quick-Clean valve on RotorRails™Cleaning is the worst! Make it better. Watch this video to learn how.

-

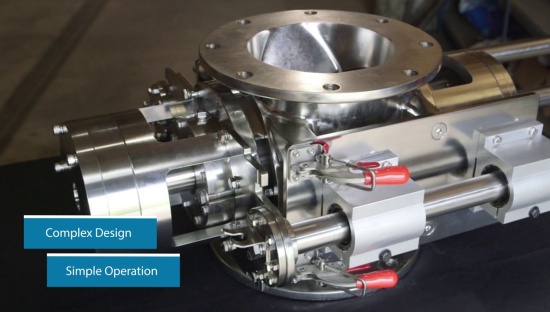

![See the Quick-Clean valve in all its glory]() See the Quick-Clean valve in all its glory

See the Quick-Clean valve in all its gloryComplex in design but simple to operate, this glamorous valve model has some serious performance to back it up.

-

![Aero-Flow Pneumatic Rotary Feeder Valve]() Aero-Flow Pneumatic Rotary Feeder Valve

Aero-Flow Pneumatic Rotary Feeder ValveA feeder valve for sticky and abrasive materials combines pressurized air with the dry bulk material.

-

![Quick-Clean Rotary Valve Demonstration]() Quick-Clean Rotary Valve Demonstration

Quick-Clean Rotary Valve DemonstrationEnables quick, tool-less access to the rotor and the interior of the housing for cleaning.

-

![ACS Valves Rotary Airlock Valve Test Center]() ACS Valves Rotary Airlock Valve Test Center

ACS Valves Rotary Airlock Valve Test CenterOur test center is designed to test your materials to determine which airlock valve/feeder is best suited for your application.

-

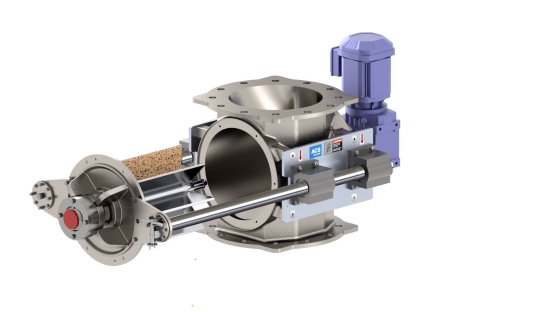

![ACS Valves Quick Clean Feeder - Pellet Feeder]() ACS Valves Quick Clean Feeder - Pellet Feeder

ACS Valves Quick Clean Feeder - Pellet FeederACS Valves Quick Clean Feeder on Rails is designed for quick take apart applications.

-

![Quick-Clean Rotary Valve]() Quick-Clean Rotary Valve

Quick-Clean Rotary ValveThis valve can be taken apart, cleaned and reassembled in just minutes hassle free!

-

![ACS Quick-Clean Airlock/Feeder]() ACS Quick-Clean Airlock/Feeder

ACS Quick-Clean Airlock/FeederThe Quick Clean feeder is easy to disassemble and reassemble, in as little as 2 minutes.

-

![ACS Valves Standard Valve Assembly]() ACS Valves Standard Valve Assembly

ACS Valves Standard Valve AssemblyThis simple rotary valve re-assembly sequence shows the significant labor and downtime savings associated with this rotary valve design

-

![ACS Valves Airlock Testing Process]() ACS Valves Airlock Testing Process

ACS Valves Airlock Testing ProcessEach rotary valve goes through a thorough inspection process before leaving ACS.

-

![ACS Valves CNC Turning Center]() ACS Valves CNC Turning Center

ACS Valves CNC Turning CenterACS Valves production operations include casting of rotary valve housings and the CNC machining of the housings.

-

![ACST-4 Glandless Shaft Seal versus Packing Gland Seals]() ACST-4 Glandless Shaft Seal versus Packing Gland Seals

ACST-4 Glandless Shaft Seal versus Packing Gland SealsEliminates the need for conventional packing gland-style shaft seals.

-

![ACST-4 Glandless Shaft Seal Removal Sequence]() ACST-4 Glandless Shaft Seal Removal Sequence

ACST-4 Glandless Shaft Seal Removal SequenceACST-4 Glandless Teflon Shaft Seal can be easily removed and reassembled in just a few minutes using basic hand tools.

-

![ACS Valves Vertical CNC Machining Center]() ACS Valves Vertical CNC Machining Center

ACS Valves Vertical CNC Machining CenterProduction operations include CNC machining of rotor blades, rotor adjustable tips, slide-gate parts, inspection panels, and metering-s

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

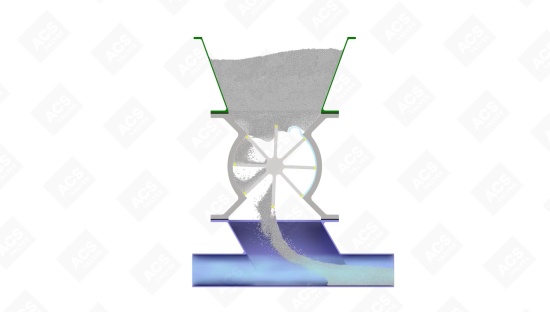

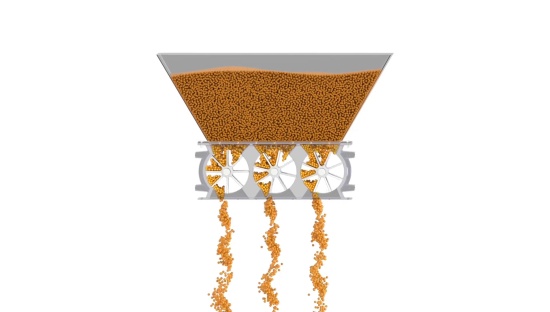

All about airlocks for metering and feeding

To combat common issues in metering and feeding applications, look for these features in rotary airlock valves.