Food Processing

Faster cleaning, better sanitation, more efficient bulk material processing, and less mess — that’s what you can expect from the ACS Valves lineup of rotary airlock valves for the food industry.

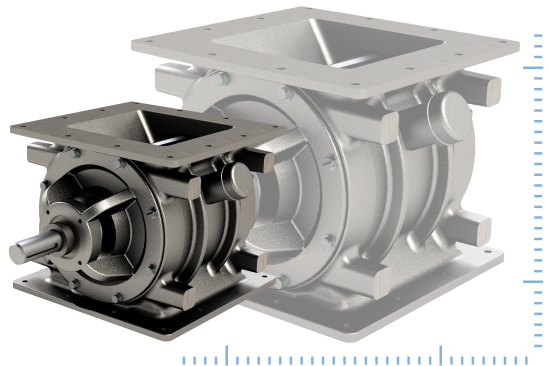

Rotary airlock valves for the food industry

Whether it’s food-grade, quick-cleaning, anti-corrosion, or all of the above, find a valve with features that fit your safety and compliance needs.

Sanitary CI with Quick-Clean RotorRail™

MD Series

MD with Quick-Clean RotorRail™

CI Series

Need help choosing the right valve?

That’s what we’re here for. Get in touch with your local ACS Valves representative to find out which valve is the best match for your food processing challenges.

In-house design services

Get design helpView rotary valve technical drawings

See drawingsCommon bulk materials

Many of our customers convey ingredients like these (and plenty of others too).

- Flour

- Sugar

- Wheat & grains

- Corn

- Nuts and seeds

- Coffee

Valve resources for the food industry

How blow-through valves keep sticky materials flowing

Read about the blow-through rotary airlock valves that improve flow for hard-to-convey materials like fine powders.

Quiz: Food safety for rotary airlock valves

Think you know a lot about food contamination? Our quiz will test how well you can apply that knowledge to rotary valves.

Valves for sugar, spice, and all things nice

Fine, powdery materials like sugar can get your equipment into sticky situations. These rotary valves help prevent build-up and corrosion

Mill more flour, corn and oat products with efficient valves

Boost productivity in your mill with rotary airlock valves for grains, flour and similar materials

Steps to Clean Your Quick-Clean Rotary Valve

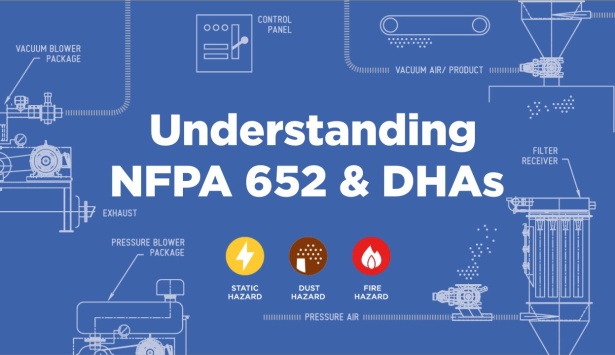

What you need to know about DHAs and NFPA 652

Will it clean?

How to convey sticky material with a blow-through

-

This link opens in a new tab

![ACS Conveying System Safety Guidelines]() ACS Conveying System Safety Guidelines

ACS Conveying System Safety GuidelinesDownload our blueprint on plant safety and print some off to keep your workers informed!

Download -

This link opens in a new tab

![ACS NFPA Pocket Guide]() ACS NFPA Pocket Guide

ACS NFPA Pocket GuideTips for NFPA compliance in your rotary valve and process

Download -

This link opens in a new tab

ACST4 Shaft Seals

ACST4 Shaft SealsUsed on both ends of the rotor shaft for a tight seal. The option of air purge connections for severe conditions are available on either shaft seal, they help keep the material from building up around the shaft seals.

Download -

This link opens in a new tab

![Rotary Valve Selector Guide]() Rotary Valve Selector Guide

Rotary Valve Selector GuideRotary Valve Selector Guide Provides In-depth Reference Information to Simplify the Evaluation, Comparison, and Selection of Rotary Valves, Rotary Feeders, and Rotary Airlocks in Bulk Material Handling and Pneumatic Conveying Applications

Download

Food industry FAQs

You asked, we answered these common questions related to the food processing industry and rotary valves.

See all FAQs-

A.

While we understand the temptation for a quick fix, we definitely don’t recommend hitting your valve with hammers, wrenches, or whatever tools you have on hand. It only damages the valve and doesn’t help with material blockage. If you need help improving material flow, speak to one of our valve experts for recommendations specific to your application.

Relevant for: Technical Support, Difficult Products -

A.

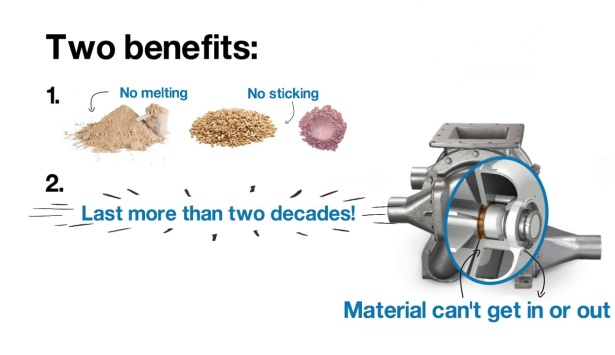

Rotary airlock valves can be specified with features that support food safety and sanitation goals. We often recommend stainless-steel materials of construction, special coatings, and valves designed on a rail system for easy disassembly and cleaning.

Relevant for: Difficult Products, Safety -

A.

We have lots, and they depend on your application. One approach is coatings, like hard chrome or the abrasion resistant XTR-Coat, which can help material slide through the valve without sticking.

Before we make this answer too complicated, check out our blog on material flow tips.

Relevant for: Difficult Products, Reliability -

A.

Rotary valves built on a rail system are specifically designed for faster cleaning, because you don’t need tools or a lot of effort to open up the valve and access the internal housing. The ACS Valves model is called the Quick-Clean, and it’s designed to help you clean up in just a few minutes. You could also add a U-shaped rotor, which has round pockets to prevent stubborn material buildup.

Configure your valve for food processing

Questions about choosing the right valve for your food processing application? That’s what we’re here for. Contact our experts to get the best tips for material flow, performance, and safety.