Pharmaceutical and Cosmetics Processing

With its delicate dry bulk ingredients, the pharmaceutical and cosmetics industry requires rotary valves that handle material with accuracy and care. Find the best options right here.

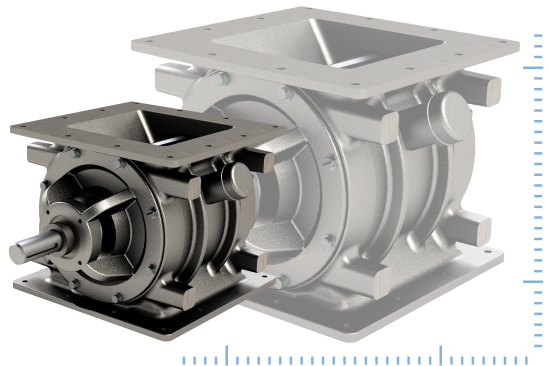

Rotary valves for pharmaceutical and cosmetics processing

With sanitary and quick-cleaning features, our valves help you meet regulatory standards while delivering consistently great performance.

Micro-Ingredient Series

MD Series

MD with Quick-Clean RotorRail™

CI Series

Need help choosing the right valve?

That’s what we’re here for. Get in touch with your local ACS Valves representative to find out which valve is the best match for your application in the pharmaceutical and cosmetics industry.

In-house design services

Get design helpView rotary valve technical drawings

See drawingsCommon bulk materials

Our customers in the pharmaceutical and cosmetics industry typically convey ingredients like these (and plenty of others too).

- Granules

- Powders

- Capsules

- Pigments

- Talc

- Silica

Valve resources for pharmaceutical and cosmetics

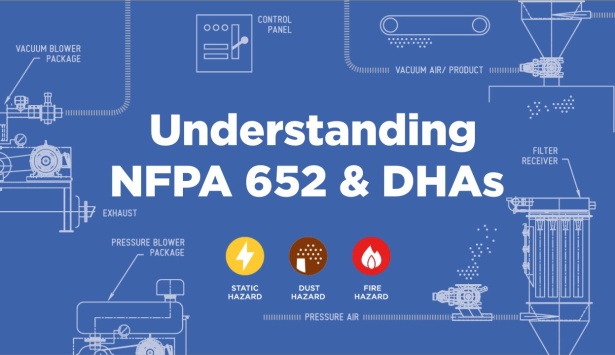

What’s new in the NFPA 660 combustible dust standard?

NFPA 660: Standard for Combustible Dusts and Particulate Solids (2025) is now in effect. Find out what the changes mean for your processing plant.

Is my rotary valve NFPA compliant?

Learn the requirements for an NFPA compliant rotary airlock valve and find out why compliance is so important.

How to: Clean a Quick-Clean Rotary Valve

Quick-Clean rotary valves are designed for fast, tool-less cleanup — just follow these steps to get it done

Avoid sticky situations with a rotary airlock feeder

The Aero-Flow feeder valve mixes material with pressurized air to prevent premature wear and boost consistency

Steps to Clean Your Quick-Clean Rotary Valve

ACS Valves: It Will Fit

What you need to know about DHAs and NFPA 652

How to convey sticky material with a blow-through

-

This link opens in a new tab

![ACS Conveying System Safety Guidelines]() ACS Conveying System Safety Guidelines

ACS Conveying System Safety GuidelinesDownload our blueprint on plant safety and print some off to keep your workers informed!

Download -

This link opens in a new tab

![ACS NFPA Pocket Guide]() ACS NFPA Pocket Guide

ACS NFPA Pocket GuideTips for NFPA compliance in your rotary valve and process

Download -

This link opens in a new tab

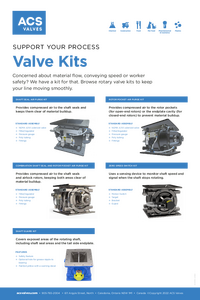

Valve Kits

Valve KitsSee an overview of the rotary airlock valve kits we provide to boost performance and process efficiency.

Download -

This link opens in a new tab

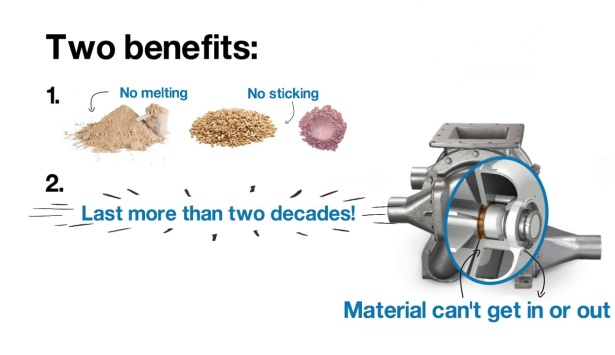

ACST4 Shaft Seals

ACST4 Shaft SealsUsed on both ends of the rotor shaft for a tight seal. The option of air purge connections for severe conditions are available on either shaft seal, they help keep the material from building up around the shaft seals.

Download

Pharmaceutical and cosmetics industry FAQs

You asked, we answered these common questions related to pharmaceutical and cosmetics processing and rotary valves.

See all FAQs-

A.

When it comes to material shearing, the first thing we tend to look at is fill capacity. Factors like your material shape and size, equipment specifications, and conveying speed influence the right fill capacity to prevent jamming and shearing. Optional accessories like adjustable shear protectors, often recommended for materials like plastic pellets and sawdust, can be useful to help things keep flowing smoothly. A valve expert can give you more specific guidance based on your application.

Relevant for: Difficult Products -

A.

Not all rotary valves are designed to be interchangeable between ingredients, but ACS Valves has options for plants with split conveying feeds or multiple ingredients. The Multi-Port valve is one to consider, since it features multiple separate compartments in a single valve, making it easier to convey materials from different lines into a single valve. Many of our customers also use the Quick-Clean valve to convey multiple ingredients, because it can be cleaned and sanitized quickly thanks to its rail-based design.

Relevant for: Conveying Systems, Manufacturing -

A.

We have lots, and they depend on your application. One approach is coatings, like hard chrome or the abrasion resistant XTR-Coat, which can help material slide through the valve without sticking.

Before we make this answer too complicated, check out our blog on material flow tips.

Relevant for: Difficult Products, Reliability -

A.

Rotor-to-housing tolerances, or clearances, are the distance between your rotor tips and valve housing. Because they wear down over time, you should measure them as part of your regular maintenance routine. Increased tolerances leave a bigger gap for material to leak through, which prevents the valve from working effectively. This can lead to issues with material flow, NFPA compliance and safety, and overall efficiency. Check them often!

Configure a valve for pharmaceutical and cosmetics processing

The accuracy and reliability of your rotary valve depends on how it’s configured. To make sure you select the right options for your application, get in touch with our experts via the form.