Construction Materials Processing

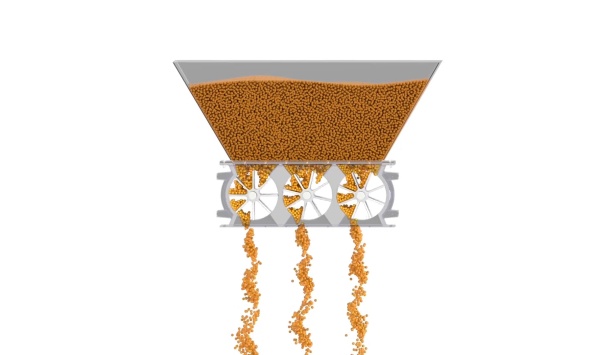

Bulk materials in the construction industry are tough on your equipment. Find a rotary valve that holds up against daily wear-and-tear to provide less maintenance and a longer lifespan.

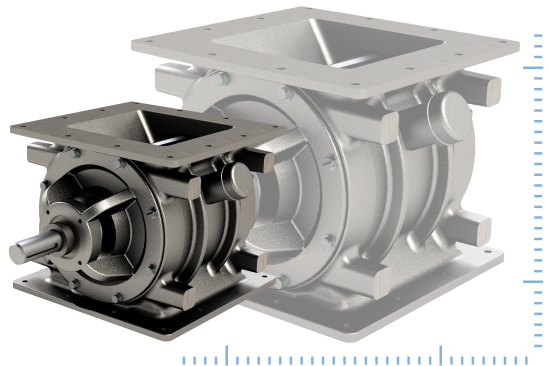

Rotary airlock valves for the construction industry

Built to withstand heavy-duty construction applications, our rotary valves will stand up to any job. Find valves with quality casting and improved longevity.

MD Series

CI Series

Aero-Flow™ Series

DR-S Series

Need help choosing the right valve?

That’s what we’re here for. Get in touch with your local ACS Valves representative to find out which valve is the best match for your construction material processing challenges.

In-house design services

Get design helpView rotary valve technical drawings

See drawingsCommon bulk materials

Our customers in the construction industry typically convey ingredients like these (and plenty of others too).

- Cement

- Asphalt

- Mineral ore

- Coal

- Gypsum

Valve resources for the construction industry

5 tips for more efficient mineral processing

With its unique material properties and complex material handling systems, mineral ore is tricky to convey. Keep these tips in mind to optimize your process.

How to: Renew rotor tip clearances

Follow these simple steps to check clearances and adjust the blades on a rotor with adjustable tips.

How are rotary valves tested for safety?

To set you up for success, the ACS Valves team puts rotary airlock valves through some really rigorous tests.

How do I configure a valve for conveying cement?

In a heavy-duty setting, durability and reliability are key. These coatings and options help rotary valves handle cement and construction materials

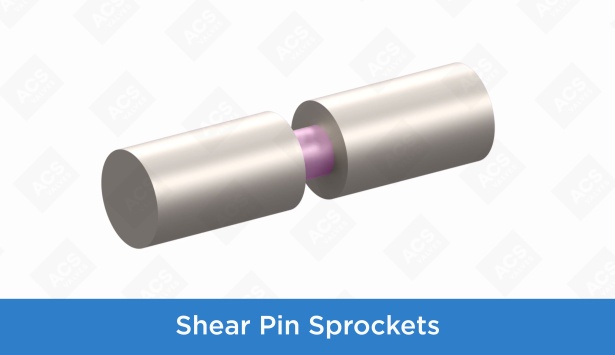

How shear pin sprockets prevent damage to your valve

Why is rotor maintenance so important?

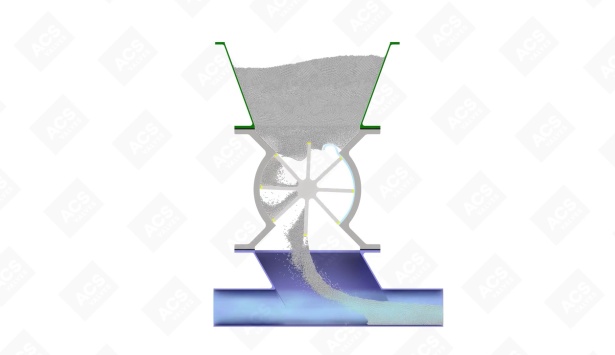

See the Multi-Port Valve at work in 3D

Drive Side Endplate Removal for ACST-4 Seals

-

This link opens in a new tab

![ACS NFPA Pocket Guide]() ACS NFPA Pocket Guide

ACS NFPA Pocket GuideTips for NFPA compliance in your rotary valve and process

Download -

This link opens in a new tab

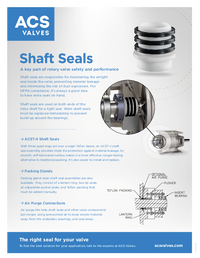

ACST4 Shaft Seals

ACST4 Shaft SealsUsed on both ends of the rotor shaft for a tight seal. The option of air purge connections for severe conditions are available on either shaft seal, they help keep the material from building up around the shaft seals.

Download -

This link opens in a new tab

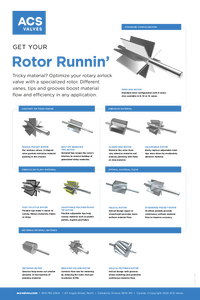

Types of Rotors

Types of RotorsOur suite of rotors work with the demands, challenges and regulations involved with a wide range of materials. Choose the rotor that’s right for your valve.

Download -

This link opens in a new tab

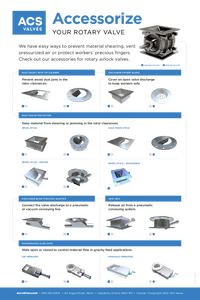

Rotary Valve Accessories

Rotary Valve AccessoriesGet a bird's eye view of the rotary airlock valve accessories we offer for added safety, efficiency and longevity.

Download

Construction industry FAQs

You asked, we answered these common questions related to the construction material processing industry and rotary valves.

See all FAQs-

A.

Rotary valves can be very effective at minimizing leakage when properly configured by an expert.

As a general recommendation to prevent dust leakage, valves should be equipped with ACST-4 shaft seals and an outboard bearing design. You should also check rotor-to-housing tolerances often, as enlarged tolerances can also cause leaks.

-

A.

While we understand the temptation for a quick fix, we definitely don’t recommend hitting your valve with hammers, wrenches, or whatever tools you have on hand. It only damages the valve and doesn’t help with material blockage. If you need help improving material flow, speak to one of our valve experts for recommendations specific to your application.

Relevant for: Technical Support, Difficult Products -

A.

The most common parts you need to replace on a regular basis include the rotor, shaft seals, and bearings. It’s a great idea to keep spare parts for your rotary valve. We have an NFPA compliance kit you can order to have the most important parts on your shelf just in case you need to make a quick replacement.

Relevant for: Technical Support, NFPA -

A.

It depends! Do you want a valve with an easy-to-clean design? A valve with multiple ports for split conveying lines? Maybe a valve for heavy-duty applications, for corrosive material, or for metering small batches?

We could go on, but the best way to determine which valve you need is to speak with an ACS Valves rep. Give us the details and we’ll help you choose a rotary valve that’s optimized for your needs.

Relevant for: Conveying Systems

Configure a valve for construction material processing

Construction materials have wide-ranging characteristics, so your rotary valve should be configured to meet the specific challenges of your application. Complete the form to ask our experts for help.