True

True

12" Multi-Port Series

Multi-compartment rotary valve for higher-volume applications or split-line conveying feedsSeparate airlock compartments for improved efficiency, uptime and NFPA compliance. Ideal for high volumes of free-flowing granular material or situations where multiple independent feeds are needed.

Downloads

Datasheet

Features & Benefits:

- Trough-style openings can be designed to fit dust collectors, hoppers, bins, silos and screw conveyors.

- Higher capacity with a smaller overall height for tight space engineered solutions.

- Tighter clearances enable NFPA compliance despite larger capacity outputs (since NFPA clearances can be challenging in larger airlocks).

- With independent drives, issues or a breakdown in one compartment can be contained and allow other compartments to continue operating.

- Common parts in a unique housing mean no special maintenance requirements. Spare parts are readily available (whereas spares for larger airlocks can have a longer lead time).

- Separate airlock compartments allow for intermittent feeds — two, three or four rotors can run simultaneously or independently for multi-line feeds.

- More compact design than other valves of its kind, which reduces stack-up in silos and dust collectors.

- Direct drives in each compartment allow for independent operation.

Options:

- Use to break up large pneumatic conveying systems into smaller, more manageable systems.

- Can be equipped with one elongated blow-through adapter to feed one system or multiple blow-through adapters for different line feeds.

- Equip with one large pressure blower package or several smaller ones for multiple systems.

Construction Blogs & Videos

Featured video

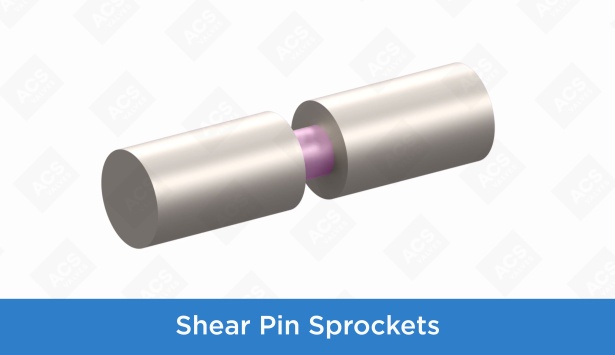

How shear pin sprockets prevent damage to your valve

Featured blog

How do I configure a valve for conveying cement?

In a heavy-duty setting, durability and reliability are key. These coatings and options help rotary valves handle cement and construction materials

Featured blog

5 tips for more efficient mineral processing

With its unique material properties and complex material handling systems, mineral ore is tricky to convey. Keep these tips in mind to optimize your process.