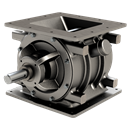

Closed End Rotor

Used with extremely abrasive material to protect the outboard bearings and endplates. Also used for flake or chip material to reduce risk of material jamming between rotor and housing.

EXPLORE IN THE 3D VIEWERInformation:

- Rotor pocket purge connections are recommend with this rotor option

Materials:

- mild steel

- stainless steel

- AR 400

May 30, 2017 by Greg Thompson

The ultimate guide to valve rotor types

Give your material some TLC and keep your rotors lasting long. Here's a guide on which rotor works best for your application.

Aug 18, 2021 by Megan Thompson

Choosing a rotary valve: 3 more things to consider

Find out how energy efficiency, NFPA safety and maintenance cycles impact your choice of rotary airlock valve

Jan 16, 2023 by Terri Shipstone

How do I configure a valve for conveying cement?

In a heavy-duty setting, durability and reliability are key. These coatings and options help rotary valves handle cement and construction materials

Jan 17, 2024 by Brittany Dollimore

5 tips for more efficient mineral processing

With its unique material properties and complex material handling systems, mineral ore is tricky to convey. Keep these tips in mind to optimize your process.

Mar 13, 2024 by Brittany Dollimore

How to choose a rotor for your valve’s application

Does your rotary airlock valve need a standard rotor or something more specific? Find out which rotor type you should choose based on your dry bulk material.

Aug 08, 2024 by Nena Dallas

Tips for conveying recycled plastic flakes

Read our plastic flake conveying tips to maintain healthy material throughput, minimize product waste, and prevent contamination.

Nov 21, 2024 by Nena Dallas

Quiz: Can you master milling with valves?

Think you know a lot about processing milled ingredients like flour and corn? Take our quiz on milling, conveying, and rotary airlock valves to find out.

Mar 17, 2025 by ACS Valves

Check out our booth at The Powder Show 2025

Find ACS Valves at booth 1509 and connect with our rotary airlock valve experts

Apr 07, 2025 by Brittany Dollimore

Why keep spare valve parts on the shelf?

Stock extra rotary airlock valve parts on the shelf to reduce downtime, protect other important components, and keep your facility safe.

May 16, 2025 by Brittany Dollimore

Quiz: Test your mineral processing know-how

Minerals are tough — conveying them can be even tougher. See if you know the answers to these questions on the basics of mineral ore processing.

Aug 14, 2025 by Paul Bowman

Quiz: Do you know these valve spare parts?

What are the most critical parts of a rotary airlock valve, when do you need to replace them, and why? Test your knowledge with this quiz.

Aug 14, 2025 by Megan Thompson

My facility handles grain-based pet foods. Are there any rotary valves or features designed to mitigate the risk of dust explosions?

According to NFPA rules, a compliant rotary valve has metal tips on the rotor assembly, outboard bearings, and rotors with eight vanes or more.

Aug 18, 2025 by Megan Thompson

3 critical valve parts for NFPA compliance

Get to know the anatomy of an NFPA compliant rotary airlock valve and the parts required to keep your facility safe.

Oct 14, 2025 by Greg Thompson

What is a rotary valve, actually?

Learn the essential components of a rotary airlock valve, some key definitions, and how valves work to convey your dry bulk materials.

Dec 10, 2025 by Brittany Dollimore

This year’s most popular rotary valve topics

In 2025, our readers enjoyed learning about NFPA 660, shear pin sprockets, signs a valve needs attention, and valves for pneumatic conveying.

Jan 19, 2026 by Brittany Dollimore

What happens if you choose the wrong airlock?

Depending on how it’s configured, a rotary airlock can either boost efficiency or cause unforeseen problems. Find out how your choice affects material flow, product integrity, equipment longevity, and more.

Jan 19, 2026 by Nena Dallas

What coatings can protect my valve from hard materials like cement, gravel, and minerals?

These are abrasive construction materials, so your rotary airlock valve will need a tough coating to withstand wear, minimize downtime, and extend its lifespan.