Plastics Processing

Accuracy and consistency come first in the plastics processing industry, and product damage is a big no-no. Find a rotary airlock valve that handles your plastics with precision.

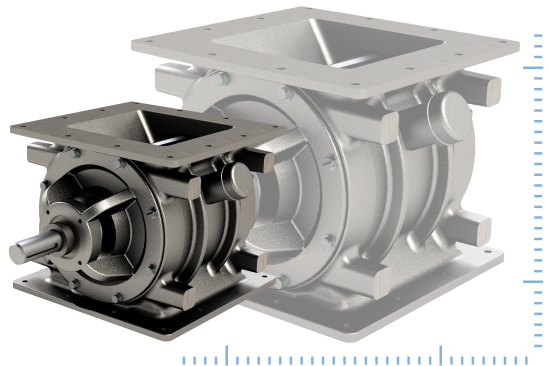

Rotary airlock valves for the plastics industry

With CNC-machined components and quality castings, our valves are engineered to prevent plastics from jamming and pinching. We also have sanitary options for food or beverage applications.

CI Series

MD Series

DR-S Series

12" Multi-Port Series

Multi-Port 12 x 36 RAL, 2.13 C.FR.

Multi-Port 12 x 48 RAL, 2.84 C.F.R.

Need help choosing the right valve?

That’s what we’re here for. Get in touch with your local ACS Valves representative to find out which valve is the best match for your plastics processing challenges.

In-house design services

Get design helpView rotary valve technical drawings

See drawingsCommon bulk materials

Our customers in the plastics industry typically convey ingredients like these (and plenty of others too).

- Pellets

- Flakes

- Regrind

- Food-grade plastic

Valve resources for the plastics industry

Tips for conveying recycled plastic flakes

Read our plastic flake conveying tips to maintain healthy material throughput, minimize product waste, and prevent contamination.

How do I keep plastic pellets intact in conveying?

For the best end product, it’s important to keep plastic pellets in a uniform shape and size. Learn the best rotary valve configurations and tips to prevent issues.

Here’s how we configure rotary airlock valves

Rotary valves, like hot dogs, have lots of customization options. Learn how we do it at ACS

Avoid rotary valve jams with adjustable shear protectors

Adjustable shear protectors prevent jamming, keep materials intact and maintain an efficient fill capacity

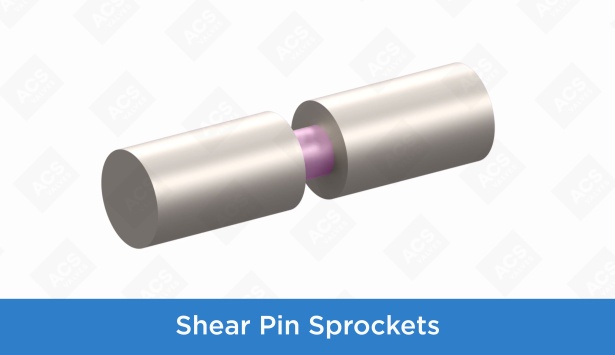

How shear pin sprockets prevent damage to your valve

Steps to Clean Your Quick-Clean Rotary Valve

A 3D view of material flow in an MD Series rotary airlock valve

ACS Valves: It Will Fit

-

This link opens in a new tab

Valve Kits

Valve KitsSee an overview of the rotary airlock valve kits we provide to boost performance and process efficiency.

Download -

This link opens in a new tab

Rotary Valve Accessories

Rotary Valve AccessoriesGet a bird's eye view of the rotary airlock valve accessories we offer for added safety, efficiency and longevity.

Download -

This link opens in a new tab

![S-Pellet Series: Rotary Valve - Spec Sheet]() S-Pellet Series: Rotary Valve - Spec Sheet

S-Pellet Series: Rotary Valve - Spec SheetThe S-Pellet Series valves, with ACS RotorRail™ quick-clean design, provide tool-less, single-step access to rotor and internal surfaces.

Download -

This link opens in a new tab

![S-Pellet Series with Quick-Clean RotorRail]() S-Pellet Series with Quick-Clean RotorRail

S-Pellet Series with Quick-Clean RotorRailThe S-Pellet Series valves, with ACS RotorRail quick-clean design, provide tool-less, single-step access to rotor and internal surfaces.

Download

Plastics industry FAQs

You asked, we answered these common questions related to the plastics processing industry and rotary valves.

See all FAQs-

A.

While we understand the temptation for a quick fix, we definitely don’t recommend hitting your valve with hammers, wrenches, or whatever tools you have on hand. It only damages the valve and doesn’t help with material blockage. If you need help improving material flow, speak to one of our valve experts for recommendations specific to your application.

Relevant for: Technical Support, Difficult Products -

A.

When it comes to material shearing, the first thing we tend to look at is fill capacity. Factors like your material shape and size, equipment specifications, and conveying speed influence the right fill capacity to prevent jamming and shearing. Optional accessories like adjustable shear protectors, often recommended for materials like plastic pellets and sawdust, can be useful to help things keep flowing smoothly. A valve expert can give you more specific guidance based on your application.

Relevant for: Difficult Products -

A.

They can! For situations where consistent feeding is essential, we have rotary valves specifically designed for applications like pellets or metering small batches of product. To get the most accurate flow, it’s important to work with a specialist who understands your industry well enough to recommend the right valve configurations.

Relevant for: Difficult Products -

A.

It depends on your application and what you need them for – safety, material flow, overall efficiency? Our rotary valve accessory guide breaks it all down.

Configure your valve for plastics processing

Bulk plastics all have different shapes, sizes, and characteristics, so it’s important to configure a rotary valve that fits your application. Fill out the form to request help from our experts.