Chemical Industry Processing

Safety and performance are high priorities in chemical applications, and your setup should be equipped to swap materials without cross-contamination. Browse rotary valves that support sanitary and corrosion-free processing.

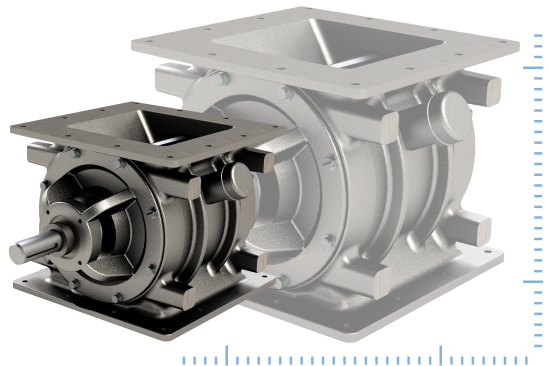

Rotary airlock valves for chemical applications

To process chemicals efficiently, you need high-performance valves with strong corrosion resistance, sanitary features, and NFPA compliance. Find them here.

MD Series

CI Series

DR-S Series

XTR-CI Series

Need help choosing the right valve?

That’s what we’re here for. Get in touch with your local ACS Valves representative to find out which valve is the best match for your chemical processing challenges.

In-house design services

Get design helpView rotary valve technical drawings

See drawingsCommon bulk materials

Our customers in the chemical industry typically convey ingredients like these (and plenty of others too).

- Fly ash

- Carbon black

- Zinc oxide

- Soda ash

- Pigments

- Detergent powders

Valve resources for the chemical industry

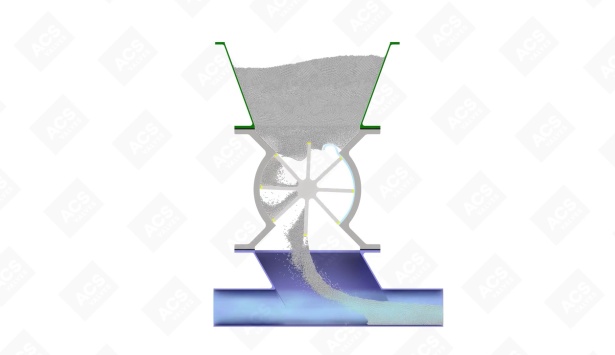

How blow-through valves keep sticky materials flowing

Read about the blow-through rotary airlock valves that improve flow for hard-to-convey materials like fine powders.

How to: Clean a Quick-Clean Rotary Valve

Quick-Clean rotary valves are designed for fast, tool-less cleanup — just follow these steps to get it done

Stand up to corrosion with the XTR Series valve

The XTR Series rotary airlock valve comes fully armored with a corrosion-resistant, food-grade coating

Layer up: An overview of coating types for rotary valves

The coating on your rotary airlock valve affects factors like material capacity, lifespan and overall performance

Why is rotor maintenance so important?

Steps to Clean Your Quick-Clean Rotary Valve

A 3D view of material flow in an MD Series rotary airlock valve

Will it clean?

-

This link opens in a new tab

![ACS NFPA Pocket Guide]() ACS NFPA Pocket Guide

ACS NFPA Pocket GuideTips for NFPA compliance in your rotary valve and process

Download -

This link opens in a new tab

![ACS Conveying System Safety Guidelines]() ACS Conveying System Safety Guidelines

ACS Conveying System Safety GuidelinesDownload our blueprint on plant safety and print some off to keep your workers informed!

Download -

This link opens in a new tab

ACST4 Shaft Seals

ACST4 Shaft SealsUsed on both ends of the rotor shaft for a tight seal. The option of air purge connections for severe conditions are available on either shaft seal, they help keep the material from building up around the shaft seals.

Download -

This link opens in a new tab

Rotary Valve Accessories

Rotary Valve AccessoriesGet a bird's eye view of the rotary airlock valve accessories we offer for added safety, efficiency and longevity.

Download

Chemical industry FAQs

You asked, we answered these common questions related to the chemical processing industry and rotary valves.

See all FAQs-

A.

Corrosive materials can damage the rotary valve’s internal parts over time, including the rotor-to-housing tolerances. We recommend a coating called XTR-Coat to minimize the effects of acidic, abrasive, or corrosive materials. Its durability prolongs the lifespan of your valve and parts, and its compliance with FDA and USDA regulations also makes it an excellent choice in many food-grade applications.

Relevant for: Difficult Products, Safety -

A.

Rotary valves built on a rail system are specifically designed for faster cleaning, because you don’t need tools or a lot of effort to open up the valve and access the internal housing. The ACS Valves model is called the Quick-Clean, and it’s designed to help you clean up in just a few minutes. You could also add a U-shaped rotor, which has round pockets to prevent stubborn material buildup.

-

A.

Not all rotary valves are designed to be interchangeable between ingredients, but ACS Valves has options for plants with split conveying feeds or multiple ingredients. The Multi-Port valve is one to consider, since it features multiple separate compartments in a single valve, making it easier to convey materials from different lines into a single valve. Many of our customers also use the Quick-Clean valve to convey multiple ingredients, because it can be cleaned and sanitized quickly thanks to its rail-based design.

Relevant for: Conveying Systems, Manufacturing

Configure your valve for chemical applications

Our experts can optimize your rotary valve to deliver the best corrosion resistance, efficiency, and lifespan for your chemical application. Complete the form to get started.