Rotor Assembly Tolerance Check

Keep valves compliant by ensuring rotor-to-housing clearance stays below 0.0079. Here's a quick video on how to check your compliance during regular maintenance on your valves.

0:04

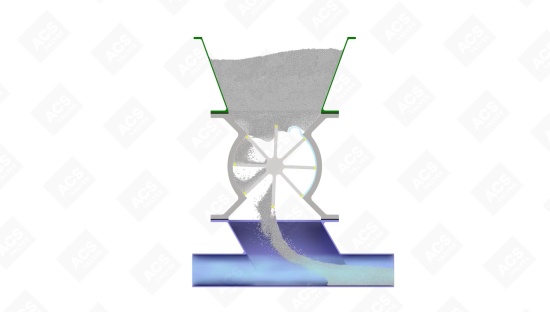

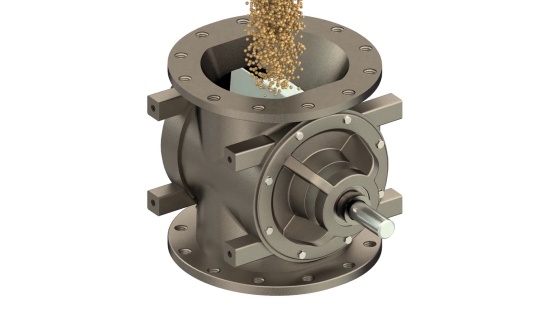

The rotary valve assembly is at the heart of the rotary valve. It acts as an airlock for the pressure difference between what is above the valve to what is below the valve. If a rotary valve is compliant with NFPA, it can help reduce the passage of flames along a conveying line should an explosion happen.

0:22

The following video outlines what those compliance rules are, as well as how to test your rotor tolerances.

0:29

So check if the valve is within tolerance for the NFPA.

0:34

You have to loosen off the set screws on the locking collars on both sides to check your side-to-side clearance first.

0:42

After you loosen off the set screws of the locking collars, you have to either punch them clockwise or counterclockwise to get the locking collars off.

0:52

Once they're off, remove, just loosen off the drive side cause the drive will be on there and pull it away from there.

1:00

You have to loosen off the split locking collar on the shaft seal on both sides.

1:07

And then get your indicator, and put it on the airlock on the end of the shaft and set it to 0.

1:21

So once everything's loosened off there, just set your indicator. Push the valve right completely to the one side endcap, whatever side you want.

1:30

And then push on the shaft and it'll show a reading of whatever the clearance is of the valve then.

1:39

So right now it's saying 8-thou, so 4-thou side clearance, which is within tolerance of the NFPA.

1:48

So after you do that, that means that the side-to-side clearances are fine for NFPA. So then you have to go about doing the outside diameter of the rotor to the housing.

2:00

So you have everything loosened off already. You have to take all the bolts out of the tail side endplates.

2:09

It's easier to do the tail side endplate because you won't have to take the drive off.

2:27

After you remove all the bolts, everything will already be loosened off from your first test that you did on the side-to-side clearance, so you should be able to just pull the endplate right off the housing.

2:48

After you do that, take your feeler gauges.

2:51

To stay compliant, at least two rotor vanes must be in contact with each side of the valve housing at all times. We recommend valves with eight vanes, as anything lower than that would be uncompliant.

3:04

And stick it under the rotor blade to the housing.

3:09

And to the top of the housing, to the rotor blade.

3:13

Until you feel friction on both feeler gauges.

3:27

Rotor tips must be of metal construction. Rubber or plastic would not be able to handle the pressure of a deflagration.

3:46

The housing-to-rotor tolerance must stay under 0.0079 inches wide, while vanes must be 3 millimeters thick.

4:06

So this airlock is 6 and 6, so that's within NFPA.

4:13

So if you're over 0.0079, then it's out of tolerance.

4:21

So you just gotta feel light friction between the housing and the rotor blade to know what your clearances are.

4:32

Then after you figure those two out, then you know if the airlock is within tolerance to the NFPA or not.

More Videos

-

![How shear pin sprockets prevent damage to your valve]() How shear pin sprockets prevent damage to your valve

How shear pin sprockets prevent damage to your valveWatch the video to see how shear pin sprockets can help you avoid unnecessary downtime and parts replacements.

-

![Why is rotor maintenance so important?]() Why is rotor maintenance so important?

Why is rotor maintenance so important?Rotor tips wear down over time, causing issues with material flow. Our video illustrates why rotor maintenance is so critical to the overall efficiency of your rotary airlock valve.

-

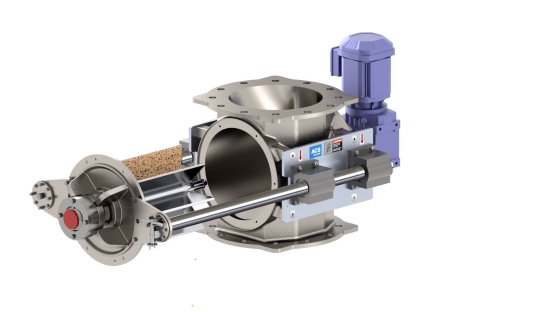

![See the Multi-Port Valve at work in 3D]() See the Multi-Port Valve at work in 3D

See the Multi-Port Valve at work in 3DLearn about the features of our Multi-Port rotary airlock valve as it conveys high volumes of material in different conveying scenarios: one line, split feeds, and varying types of equipment.

-

![Steps to Clean Your Quick-Clean Rotary Valve]() Steps to Clean Your Quick-Clean Rotary Valve

Steps to Clean Your Quick-Clean Rotary ValveCleaning a Quick-Clean rotary valve is simple! This animation offers a step by step instruction on how to do it.

-

![A 3D view of material flow in an MD Series rotary airlock valve]() A 3D view of material flow in an MD Series rotary airlock valve

A 3D view of material flow in an MD Series rotary airlock valveWatch a quick 3D demonstration of material flow and pocket fill in an MD series rotary airlock valve. The video is silent.

-

![Drive Side Endplate Removal for ACST-4 Seals]() Drive Side Endplate Removal for ACST-4 Seals

Drive Side Endplate Removal for ACST-4 SealsNeed a guide to removing the drive side endplate on your ACST-4 seals? Watch a quick visual breakdown of the process. The video is silent.

-

![ACS Valves: It Will Fit]() ACS Valves: It Will Fit

ACS Valves: It Will FitOur valves will fit literally anywhere. Watch the video to find your industry.

-

![Rotor Assembly Tolerance Check]() Rotor Assembly Tolerance Check

Rotor Assembly Tolerance CheckKeep valves compliant by ensuring rotor-to-housing clearance stays below 0.0079.

-

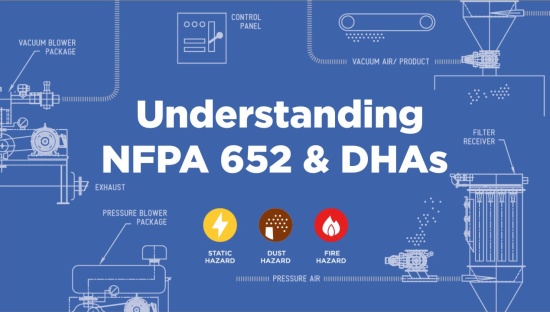

![What you need to know about DHAs and NFPA 652]() What you need to know about DHAs and NFPA 652

What you need to know about DHAs and NFPA 652Every material is different, so every valve has to be designed to handle each combustible dust in order to prevent deflagration.

-

![Will it clean?]() Will it clean?

Will it clean?We talk a lot about how easy it is to clean our valves. Watch as we put our dinner into one of our valves and then clean it up!

-

![Yes, you have to remove our endplates to replace the shaft seal]() Yes, you have to remove our endplates to replace the shaft seal

Yes, you have to remove our endplates to replace the shaft sealWe're facing our critics head on.

-

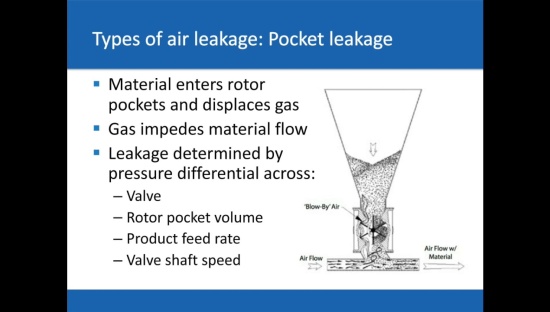

![Understanding Airlocks: The key to increasing ROI]() Understanding Airlocks: The key to increasing ROI

Understanding Airlocks: The key to increasing ROILearn the fundamentals of airlock performance, how to minimize air leakage and how improve efficiency.

-

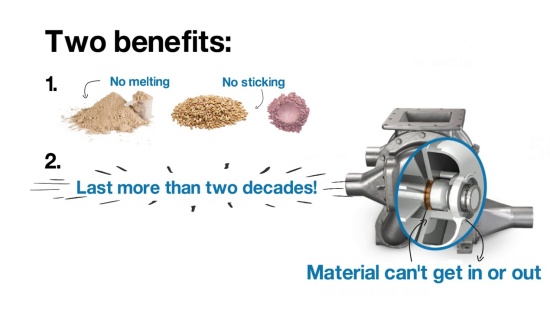

![How to convey sticky material with a blow-through]() How to convey sticky material with a blow-through

How to convey sticky material with a blow-throughWhen conveying sticky material, you can get the benefits of a blow-through without the premature wear.

-

![Why you can't afford an unreliable valve]() Why you can't afford an unreliable valve

Why you can't afford an unreliable valveChoosing the right rotary valve can improve your productivity. Choosing the wrong one can do the opposite.

-

![Make cleaning suck less with our Quick-Clean valve on RotorRails™]() Make cleaning suck less with our Quick-Clean valve on RotorRails™

Make cleaning suck less with our Quick-Clean valve on RotorRails™Cleaning is the worst! Make it better. Watch this video to learn how.

-

![See the Quick-Clean valve in all its glory]() See the Quick-Clean valve in all its glory

See the Quick-Clean valve in all its gloryComplex in design but simple to operate, this glamorous valve model has some serious performance to back it up.

-

![Aero-Flow Pneumatic Rotary Feeder Valve]() Aero-Flow Pneumatic Rotary Feeder Valve

Aero-Flow Pneumatic Rotary Feeder ValveA feeder valve for sticky and abrasive materials combines pressurized air with the dry bulk material.

-

![Quick-Clean Rotary Valve Demonstration]() Quick-Clean Rotary Valve Demonstration

Quick-Clean Rotary Valve DemonstrationEnables quick, tool-less access to the rotor and the interior of the housing for cleaning.

-

![ACS Valves Rotary Airlock Valve Test Center]() ACS Valves Rotary Airlock Valve Test Center

ACS Valves Rotary Airlock Valve Test CenterOur test center is designed to test your materials to determine which airlock valve/feeder is best suited for your application.

-

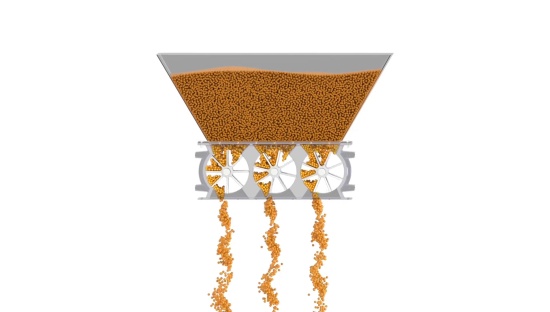

![ACS Valves Quick Clean Feeder - Pellet Feeder]() ACS Valves Quick Clean Feeder - Pellet Feeder

ACS Valves Quick Clean Feeder - Pellet FeederACS Valves Quick Clean Feeder on Rails is designed for quick take apart applications.

-

![Quick-Clean Rotary Valve]() Quick-Clean Rotary Valve

Quick-Clean Rotary ValveThis valve can be taken apart, cleaned and reassembled in just minutes hassle free!

-

![ACS Quick-Clean Airlock/Feeder]() ACS Quick-Clean Airlock/Feeder

ACS Quick-Clean Airlock/FeederThe Quick Clean feeder is easy to disassemble and reassemble, in as little as 2 minutes.

-

![ACS Valves Standard Valve Assembly]() ACS Valves Standard Valve Assembly

ACS Valves Standard Valve AssemblyThis simple rotary valve re-assembly sequence shows the significant labor and downtime savings associated with this rotary valve design

-

![ACS Valves Airlock Testing Process]() ACS Valves Airlock Testing Process

ACS Valves Airlock Testing ProcessEach rotary valve goes through a thorough inspection process before leaving ACS.

-

![ACS Valves CNC Turning Center]() ACS Valves CNC Turning Center

ACS Valves CNC Turning CenterACS Valves production operations include casting of rotary valve housings and the CNC machining of the housings.

-

![ACST-4 Glandless Shaft Seal versus Packing Gland Seals]() ACST-4 Glandless Shaft Seal versus Packing Gland Seals

ACST-4 Glandless Shaft Seal versus Packing Gland SealsEliminates the need for conventional packing gland-style shaft seals.

-

![ACST-4 Glandless Shaft Seal Removal Sequence]() ACST-4 Glandless Shaft Seal Removal Sequence

ACST-4 Glandless Shaft Seal Removal SequenceACST-4 Glandless Teflon Shaft Seal can be easily removed and reassembled in just a few minutes using basic hand tools.

-

![ACS Valves Vertical CNC Machining Center]() ACS Valves Vertical CNC Machining Center

ACS Valves Vertical CNC Machining CenterProduction operations include CNC machining of rotor blades, rotor adjustable tips, slide-gate parts, inspection panels, and metering-s

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

All about airlocks for metering and feeding

To combat common issues in metering and feeding applications, look for these features in rotary airlock valves.