Valves for Metering / Feeding

Metering and Feeding

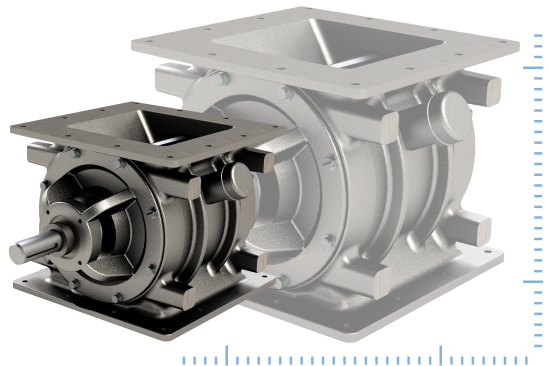

ACS Valves rotary feeders and valves are designed to ensure optimal bulk density and conveying efficiency of agglomerated materials, as well as materials that are known to over-aerate. Features such as 8-vane rotors and vent ports integrated into the rotary valve feeder housing maximize the air flow path through the rotor pockets, which improves material release. In bulk material feeding and metering applications, our rotary feeders and valves improve throughput and reduce total energy consumption.

Jump to

Rotary valves for metering and feeding

Select a valve to learn more

Recommended Valves (1/4)

MD Series

Inlet/Outlet Flange Sizes: 7 sizes from 4" to 16"

Material of Construction: Cast Iron, Stainless Steel

Pressure Differential: Up to 22 PSIG

High Temperature Range: 750°F

CI Series

Inlet/Outlet Flange Sizes: 11 sizes from 6" to 26"

Material of Construction: Cast Iron, Stainless Steel

Pressure Differential: Up to 22 PSIG

High Temperature Range: 750°F

Micro-Ingredient Series

Inlet/Outlet Flange Sizes: 1.5" to 3"

Material of Construction: Aluminum, Stainless Steel

12" Multi-Port Series

Inlet/Outlet 3 Flange Sizes: Multi-Port 12 x 24 RAL, 1.42 C.F.R.

Multi-Port 12 x 36 RAL, 2.13 C.FR.

Multi-Port 12 x 48 RAL, 2.84 C.F.R.

Multi-Port 12 x 36 RAL, 2.13 C.FR.

Multi-Port 12 x 48 RAL, 2.84 C.F.R.

Material of Construction: Cast Iron, Stainless Steel

Pressure Differential: Up to 20 PSIG

High Temperature Range: 450°F Max

Need help choosing the right valve?