Pet Food Processing

Meet the pet food industry’s demanding regulations with rotary airlock valves designed for sanitary conveying, fast and easy cleaning, and overall efficiency.

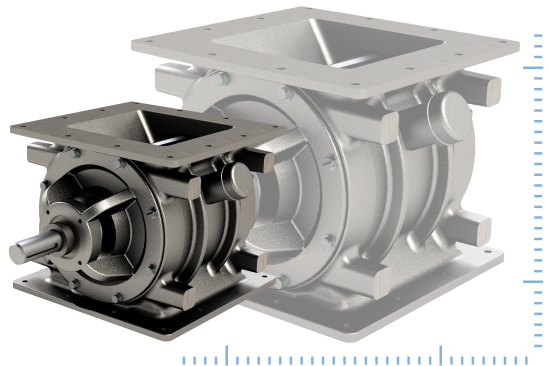

Rotary airlock valves for pet food processing

Find valves with quick-cleaning features, sanitary materials of construction, and anti-stick coatings to support your pet food conveying process.

Sanitary CI with Quick-Clean RotorRail™

MD Series

MD with Quick-Clean RotorRail™

CI Series

Need help choosing the right valve?

That’s what we’re here for. Get in touch with your local ACS Valves representative to find out which valve is the best match for your pet food processing challenges.

In-house design services

Get design helpView rotary valve technical drawings

See drawingsCommon bulk materials

Our customers in the pet food industry typically convey ingredients like these (and plenty of others too).

- Meat, fish, and bone meal

- Wheat, soybean, and corn gluten meal

- Rice, wheat, and other grains

- Premixes and additives

- Vitamin powders

- Finished pet food

Valve resources for the pet food industry

How blow-through valves keep sticky materials flowing

Read about the blow-through rotary airlock valves that improve flow for hard-to-convey materials like fine powders.

Fail-safe food safety tips for rotary valves

The regulatory landscape is always changing, but there are surefire steps you can take to keep your valves and conveying systems free of contamination.

5 pet food trends and tips for processors

As pet owners become more invested in finding the perfect munchies for their furry babies, what trends should bulk material processors keep an eye on this year?

Know your material: 8 characteristics defined

Understand these bulk material characteristics and how they affect your choice of rotary valve and other equipment

Steps to Clean Your Quick-Clean Rotary Valve

A 3D view of material flow in an MD Series rotary airlock valve

What you need to know about DHAs and NFPA 652

Will it clean?

-

This link opens in a new tab

![ACS Conveying System Safety Guidelines]() ACS Conveying System Safety Guidelines

ACS Conveying System Safety GuidelinesDownload our blueprint on plant safety and print some off to keep your workers informed!

Download -

This link opens in a new tab

![ACS NFPA Pocket Guide]() ACS NFPA Pocket Guide

ACS NFPA Pocket GuideTips for NFPA compliance in your rotary valve and process

Download -

This link opens in a new tab

![Rotary Valve Selector Guide]() Rotary Valve Selector Guide

Rotary Valve Selector GuideRotary Valve Selector Guide Provides In-depth Reference Information to Simplify the Evaluation, Comparison, and Selection of Rotary Valves, Rotary Feeders, and Rotary Airlocks in Bulk Material Handling and Pneumatic Conveying Applications

Download -

This link opens in a new tab

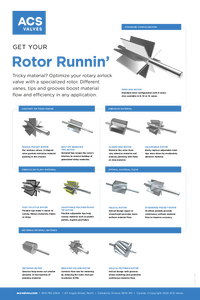

Types of Rotors

Types of RotorsOur suite of rotors work with the demands, challenges and regulations involved with a wide range of materials. Choose the rotor that’s right for your valve.

Download

Pet food industry FAQs

You asked, we answered these common questions related to the pet food processing industry and rotary valves.

See all FAQs-

A.

Not all rotary valves are designed to be interchangeable between ingredients, but ACS Valves has options for plants with split conveying feeds or multiple ingredients. The Multi-Port valve is one to consider, since it features multiple separate compartments in a single valve, making it easier to convey materials from different lines into a single valve. Many of our customers also use the Quick-Clean valve to convey multiple ingredients, because it can be cleaned and sanitized quickly thanks to its rail-based design.

Relevant for: Conveying Systems, Manufacturing -

A.

Whether you’re conveying ingredients for medicated pet foods, kibble with allergen control, or any pet food that must adhere to strict food safety guidelines, it’s important to prevent cross-contamination between batches. Make sure your valve is designed with outboard bearings and reliable shaft seals that are easy to replace.

To quickly wipe away residual product that may harbor bacteria, choose a Quick-Clean design, which allows you to open up the valve without tools for fast and easy cleaning. You might also consider sanitary materials and coatings, such as stainless-steel and XTR-Coat.

Relevant for: Difficult Products, Safety -

A.

Capacity is the volume of material your rotary valve can handle per rotation. The calculation involves the rate of conveying, material bulk density, valve efficiency, and RPM of your rotor. We can help you with the math, but if you're just looking for a valve sizing recommendation, you can use our handy calculator tool.

Relevant for: Conveying Systems, Technical Support -

A.

Rotary valves built on a rail system are specifically designed for faster cleaning, because you don’t need tools or a lot of effort to open up the valve and access the internal housing. The ACS Valves model is called the Quick-Clean, and it’s designed to help you clean up in just a few minutes. You could also add a U-shaped rotor, which has round pockets to prevent stubborn material buildup.

Configure your valve for pet food processing

Time is money in the pet food industry. To configure a rotary valve for maximum efficiency and uptime in your application, contact our experts via the online form.