Videos

Material jams can damage vital parts of your rotary valve and lead to costly repairs. Watch the video to see how shear pin sprockets can help you avoid unnecessary downtime and parts replacements.

Rotary valves can jam up causing downtime.

00:09

This is especially true in running sawdust, wood chips, or any pelleted materials.

00:17

First we will look at a standard set up.

00:20

The gear motor is turning a small sprocket which transfers

00:23

its rotation through the chain to the large sprocket.

00:27

The large sprocket drives the rotor.

00:30

A typical speed of the rotor is 20 RPM.

00:34

Here we see a rotor jam occurring.

00:36

The rotor slows down and then stops.

00:39

The large sprocket stops while the motorized small sprocket

00:42

continues to strain.

00:44

This stresses the motor shaft, both sprockets, the chain and

00:48

the rotor shaft.

00:51

The chain breaks.

00:56

Even a slight bend in the shaft makes the rotor unusable.

00:59

Same for the motor.

01:02

Here we have isolated the large sprocket and we'll look at a

01:05

better alternative.

01:07

This simple sprocket will be replaced by a shear pin

01:10

sprocket.

01:13

The shear pin will break before the chain breaks or any shafts

01:17

bend.

01:18

Let's look at the components of the shear pin sprocket.

01:25

In this exploded assembly, Note 3 critical parts: shear pin, hub and sprocket.

01:33

The shear pin is the key to this improved system.

01:37

This tiny waist will shear before any damage is done to the

01:41

chain, motor, sprockets or rotor.

01:45

The shear pin waist, which has a calculated diameter based on

01:48

load conditions, is ready to shear.

01:51

Think of it as a fuse in an electric circuit.

01:54

Let's reassemble the shear pin sprocket and see it in action.

02:01

The simple sprocket is now replaced by the shear pin

02:04

sprocket assembly.

2:07

If the shear pin breaks, the large sprocket continues to spin

02:10

but it's hub will stop.

02:12

This protects the chains, sprockets and more importantly

02:15

the motor and rotor shafts.

02:18

It's a good idea to have a zero speed switch attached to indicate stoppages.

02:24

Here the shear pin sprocket is in place and ready to run.

02:29

Now we are back running at 20 RPM.

02:33

At the start of any jam there is a very slight strain on the

02:36

chain.

02:37

Note that the shear pin is feeling the strain as well.

02:42

The shear pin is now experiencing its breaking torque.

02:48

The shear pin breaks but the large sprocket continues to spin, freewheeling.

02:55

Only its hub is stopped and this protects the chain and more importantly the motor and rotor shafts.

03:01

A zero speed switch will signal that the valve is down.

03:05

Before proceeding, lockout the power, then free up the jam.

03:10

Push out the shear pin remnants and replace with a new shear pin.

03:14

The alternative that avoids chain breakage and stops permanent

03:18

damage to the sprockets and shafts.

03:23

If you have any questions please contact us.

03:26

Contact information is on our website www.acsvalves.com.

More Videos

-

![How shear pin sprockets prevent damage to your valve]() How shear pin sprockets prevent damage to your valve

How shear pin sprockets prevent damage to your valveWatch the video to see how shear pin sprockets can help you avoid unnecessary downtime and parts replacements.

-

![Why is rotor maintenance so important?]() Why is rotor maintenance so important?

Why is rotor maintenance so important?Rotor tips wear down over time, causing issues with material flow. Our video illustrates why rotor maintenance is so critical to the overall efficiency of your rotary airlock valve.

-

![See the Multi-Port Valve at work in 3D]() See the Multi-Port Valve at work in 3D

See the Multi-Port Valve at work in 3DLearn about the features of our Multi-Port rotary airlock valve as it conveys high volumes of material in different conveying scenarios: one line, split feeds, and varying types of equipment.

-

![Steps to Clean Your Quick-Clean Rotary Valve]() Steps to Clean Your Quick-Clean Rotary Valve

Steps to Clean Your Quick-Clean Rotary ValveCleaning a Quick-Clean rotary valve is simple! This animation offers a step by step instruction on how to do it.

-

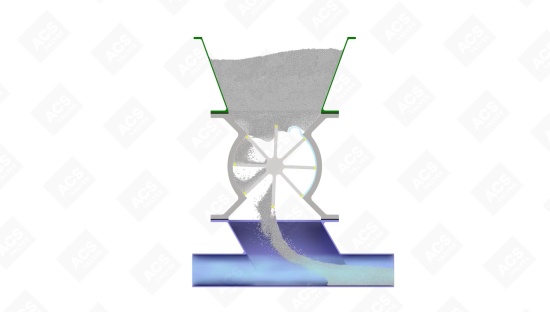

![A 3D view of material flow in an MD Series rotary airlock valve]() A 3D view of material flow in an MD Series rotary airlock valve

A 3D view of material flow in an MD Series rotary airlock valveWatch a quick 3D demonstration of material flow and pocket fill in an MD series rotary airlock valve. The video is silent.

-

![Drive Side Endplate Removal for ACST-4 Seals]() Drive Side Endplate Removal for ACST-4 Seals

Drive Side Endplate Removal for ACST-4 SealsNeed a guide to removing the drive side endplate on your ACST-4 seals? Watch a quick visual breakdown of the process. The video is silent.

-

![ACS Valves: It Will Fit]() ACS Valves: It Will Fit

ACS Valves: It Will FitOur valves will fit literally anywhere. Watch the video to find your industry.

-

![Rotor Assembly Tolerance Check]() Rotor Assembly Tolerance Check

Rotor Assembly Tolerance CheckKeep valves compliant by ensuring rotor-to-housing clearance stays below 0.0079.

-

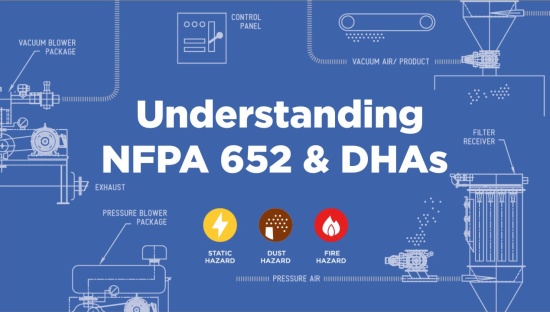

![What you need to know about DHAs and NFPA 652]() What you need to know about DHAs and NFPA 652

What you need to know about DHAs and NFPA 652Every material is different, so every valve has to be designed to handle each combustible dust in order to prevent deflagration.

-

![Will it clean?]() Will it clean?

Will it clean?We talk a lot about how easy it is to clean our valves. Watch as we put our dinner into one of our valves and then clean it up!

-

![Yes, you have to remove our endplates to replace the shaft seal]() Yes, you have to remove our endplates to replace the shaft seal

Yes, you have to remove our endplates to replace the shaft sealWe're facing our critics head on.

-

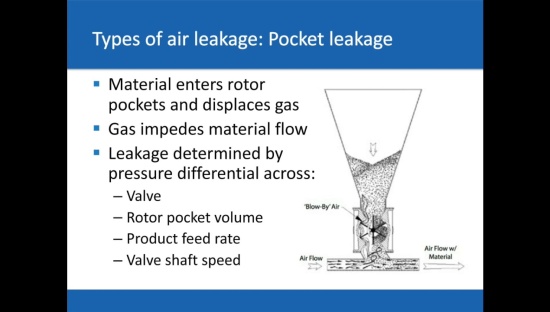

![Understanding Airlocks: The key to increasing ROI]() Understanding Airlocks: The key to increasing ROI

Understanding Airlocks: The key to increasing ROILearn the fundamentals of airlock performance, how to minimize air leakage and how improve efficiency.

-

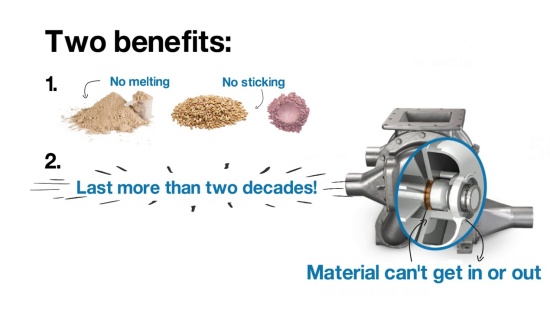

![How to convey sticky material with a blow-through]() How to convey sticky material with a blow-through

How to convey sticky material with a blow-throughWhen conveying sticky material, you can get the benefits of a blow-through without the premature wear.

-

![Why you can't afford an unreliable valve]() Why you can't afford an unreliable valve

Why you can't afford an unreliable valveChoosing the right rotary valve can improve your productivity. Choosing the wrong one can do the opposite.

-

![Make cleaning suck less with our Quick-Clean valve on RotorRails™]() Make cleaning suck less with our Quick-Clean valve on RotorRails™

Make cleaning suck less with our Quick-Clean valve on RotorRails™Cleaning is the worst! Make it better. Watch this video to learn how.

-

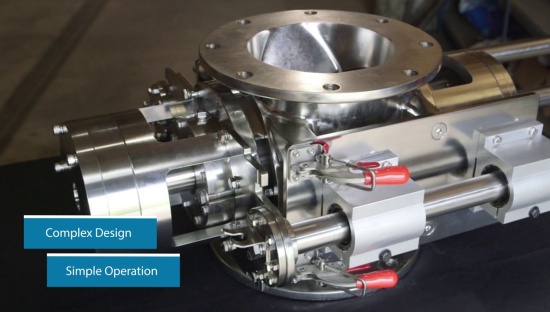

![See the Quick-Clean valve in all its glory]() See the Quick-Clean valve in all its glory

See the Quick-Clean valve in all its gloryComplex in design but simple to operate, this glamorous valve model has some serious performance to back it up.

-

![Aero-Flow Pneumatic Rotary Feeder Valve]() Aero-Flow Pneumatic Rotary Feeder Valve

Aero-Flow Pneumatic Rotary Feeder ValveA feeder valve for sticky and abrasive materials combines pressurized air with the dry bulk material.

-

![Quick-Clean Rotary Valve Demonstration]() Quick-Clean Rotary Valve Demonstration

Quick-Clean Rotary Valve DemonstrationEnables quick, tool-less access to the rotor and the interior of the housing for cleaning.

-

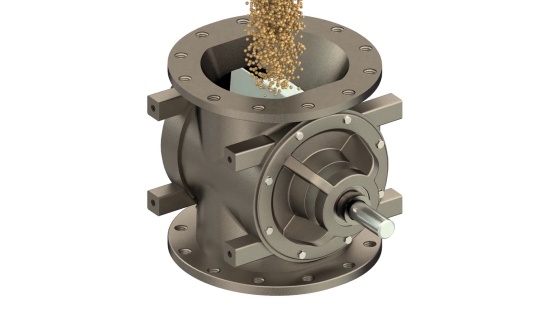

![ACS Valves Rotary Airlock Valve Test Center]() ACS Valves Rotary Airlock Valve Test Center

ACS Valves Rotary Airlock Valve Test CenterOur test center is designed to test your materials to determine which airlock valve/feeder is best suited for your application.

-

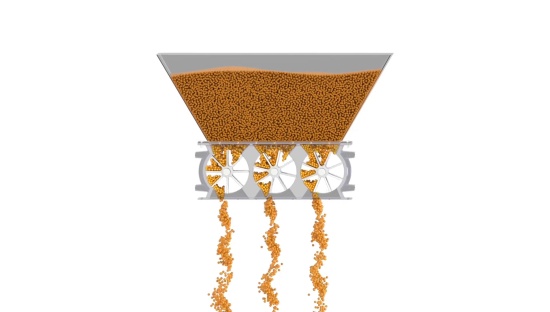

![ACS Valves Quick Clean Feeder - Pellet Feeder]() ACS Valves Quick Clean Feeder - Pellet Feeder

ACS Valves Quick Clean Feeder - Pellet FeederACS Valves Quick Clean Feeder on Rails is designed for quick take apart applications.

-

![Quick-Clean Rotary Valve]() Quick-Clean Rotary Valve

Quick-Clean Rotary ValveThis valve can be taken apart, cleaned and reassembled in just minutes hassle free!

-

![ACS Quick-Clean Airlock/Feeder]() ACS Quick-Clean Airlock/Feeder

ACS Quick-Clean Airlock/FeederThe Quick Clean feeder is easy to disassemble and reassemble, in as little as 2 minutes.

-

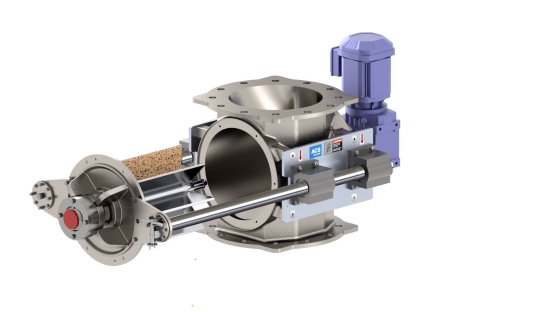

![ACS Valves Standard Valve Assembly]() ACS Valves Standard Valve Assembly

ACS Valves Standard Valve AssemblyThis simple rotary valve re-assembly sequence shows the significant labor and downtime savings associated with this rotary valve design

-

![ACS Valves Airlock Testing Process]() ACS Valves Airlock Testing Process

ACS Valves Airlock Testing ProcessEach rotary valve goes through a thorough inspection process before leaving ACS.

-

![ACS Valves CNC Turning Center]() ACS Valves CNC Turning Center

ACS Valves CNC Turning CenterACS Valves production operations include casting of rotary valve housings and the CNC machining of the housings.

-

![ACST-4 Glandless Shaft Seal versus Packing Gland Seals]() ACST-4 Glandless Shaft Seal versus Packing Gland Seals

ACST-4 Glandless Shaft Seal versus Packing Gland SealsEliminates the need for conventional packing gland-style shaft seals.

-

![ACST-4 Glandless Shaft Seal Removal Sequence]() ACST-4 Glandless Shaft Seal Removal Sequence

ACST-4 Glandless Shaft Seal Removal SequenceACST-4 Glandless Teflon Shaft Seal can be easily removed and reassembled in just a few minutes using basic hand tools.

-

![ACS Valves Vertical CNC Machining Center]() ACS Valves Vertical CNC Machining Center

ACS Valves Vertical CNC Machining CenterProduction operations include CNC machining of rotor blades, rotor adjustable tips, slide-gate parts, inspection panels, and metering-s

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

What happens if you choose the wrong airlock?

Depending on how it’s configured, a rotary airlock can either boost efficiency or cause unforeseen problems. Find out how your choice affects material flow, product integrity, equipment longevity, and more.