CI-RPV Series

Rotary Valve for Metering, Feeding and Airlock ApplicationsRotary plug valve (RPV) design provides highly accurate, controlled feeding of very free-flowing, abrasive, and high bulk density materials; excellent dust control design.

Downloads

Datasheet

Features & Benefits:

- Rotary plug valve (RPV) design provides highly accurate, controlled feeding of very free-flowing, abrasive, and high bulk density materials; excellent dust control design.

- Air-actuated clam-style rotor enables rapid material flow control and exceptional air handling efficiency in high-pressure differential applications.

- Air control package includes solenoid, fittings, and tubing; pre-assembled and ready for start-up.

- Available in 5 heights, from 10"H to 19"H; and 5 square-flange sizes from 6" to 14".

- Valve housing and endplates cast in North America; ensures superior strength and solidification of metallurgy; air cylinder mount fabricated of mild steel.

- CNC-machined components and housing provide precision tolerances; eliminates axial shaft movement.

- Heavy-plate chrome interior.

Options:

- 304 or 316 cast stainless steel valve housing.

- Interior coating: hard chrome.

- Actuator types: electrical or manual.

Construction Blogs & Videos

Featured video

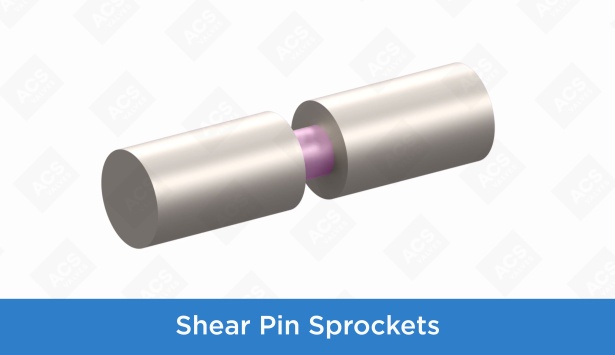

How shear pin sprockets prevent damage to your valve

Featured blog

How do I configure a valve for conveying cement?

In a heavy-duty setting, durability and reliability are key. These coatings and options help rotary valves handle cement and construction materials

Featured blog

5 tips for more efficient mineral processing

With its unique material properties and complex material handling systems, mineral ore is tricky to convey. Keep these tips in mind to optimize your process.