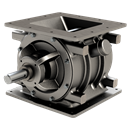

Vacuum Blower Package for Conveying Systems

High-performance, High-efficiency Positive Displacement Systems

Blower system design provides vacuum conveying functions for dry bulk material handling operations requiring optimal balance of blower power and energy efficiency.

Size Range:

3 to 200 HP

100 to 3500 CFM

15 Hg max

Features & Benefits:

- Blower system design provides vacuum conveying functions for dry bulk material handling operations requiring optimal balance of blower power and energy efficiency.

- Fully assembled system built on mild steel skid with complete side-protection frame; primed and painted.

- Roots positive displacement blower; sized and specified to application-specific requirements.

- High-efficiency, TEFC motor.

- Adjustable motor base; accommodates multiple motor types, simplifies standards compliance.

- V-belt drive simplifies maintenance, runs quietly; drive guard protects personnel.

- Vacuum relief valve maintains tight seal till tank pressure reaches relief setting.

- Vacuum breaker valve

- Vacuum switch

- Inlet filter protects system from introduction of damaging, harmful contaminants.

- Inlet & discharge silencers

- Back check valve enables proper flow and pressure.

- Vacuum gauge provides accurate monitoring and measure; aids in system optimization and efficiency.

- Discharge expansion joint enables consistent pressure levels in operations with varied temperatures.

Options:

- Customer-specific positive displacement blower brands and specifications.

- Customer-specific paint and finish coatings.

- Sound enclosure vibration pads