Valve questions? We have answers.

When you ask our team of industry experts, you draw from decades of knowledge about rotary airlock valves and conveying systems.

Meet our valve experts

Brittany heads up our sales team with more than 15 years in the bulk processing industry, which means she has some of the best all-around knowledge about rotary airlock valve configuration.

Whether you’re trying out new ingredients or need to make a switch, Terri’s material expertise can help you keep machinery clean and boost efficiency in your production process.

Need Tech Support?

Better call Paul

If you’re having trouble with a material jam, worn-out parts, or lost productivity, Paul is the one to call. He has 25 years of experience in manufacturing to help keep your equipment in ship shape.

See some of our popular FAQs

-

A.

These are abrasive construction materials, so your rotary airlock valve will need a tough coating to withstand wear, minimize downtime, and extend its lifespan. Hard chrome is a common choice, but heavy plate chrome and tungsten are also solid choices for more heavy-duty applications. Talk to a rotary valve expert to choose the right one.

Relevant for: Difficult Products, Durability -

A.

Outboard bearings are mounted on the outside of a rotary valve’s housing, while inboard bearings sit on the inside of the endplates. Because they’re located closer to the seal, inboard bearings are typically associated with more frequent repairs and a greater risk of contamination. Outboard bearings leave a gap between the seal and bearings, which makes them safer and more reliable in the long run.

Relevant for: General, Technical Support -

A.

Your options are a shaft seal air purge kit, a rotor pocket air purge kit, or a combination of both. The answer is situational, but generally the shaft seal kit is best for abrasive materials, such as cement, or very fine materials that are prone to leaking. The rotor pocket option works well for ingredients that tend to pack or build up on your equipment. If your application presents a mix of both challenges, the combo air purge kit should come in handy.

-

A.

It depends on the material, but the right valve can hold up well in abrasive applications. If you’re concerned about the valve’s lifespan and maintenance cycles, the proper configuration is key. That could mean coatings like hard chrome, heavy plate chrome, or tungsten; closed-end rotors made from stainless-steel or AR400 steel; or accessories like air purge kits.

To get the most out of your valve, contact an expert who can recommend the best options.

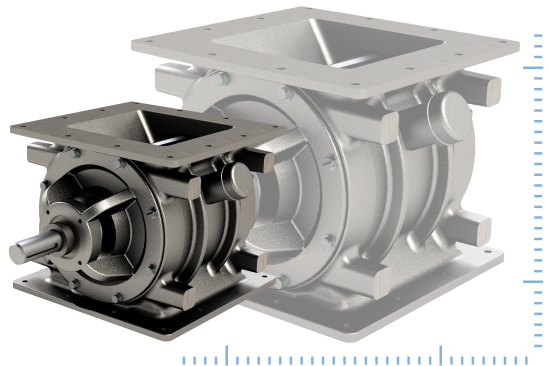

Drag, click, zoom: View our valves in 3D

Size a valve with our calculator tool

How wide does your valve’s inlet need to be? Find out quickly with our Rotary Valve Sizing Tool, a handy online calculator tool. Just enter your capacity, material bulk density, and expected efficiency.

Size my valve

Get in Touch

Ask for conveying expertiseImpressed by our bulk material conveying knowledge? We have plenty more where that came from. For answers to your specific questions, contact our rotary valve experts.