No matter how you slice it, quality always makes a difference.

Why else would we continue to improve our valves?Less downtime

More zenIf your valve is built well, it is less likely to break down, require high maintenance and leak material. Preventing these problems will save you downtime—which averages of $500 an hour per line.

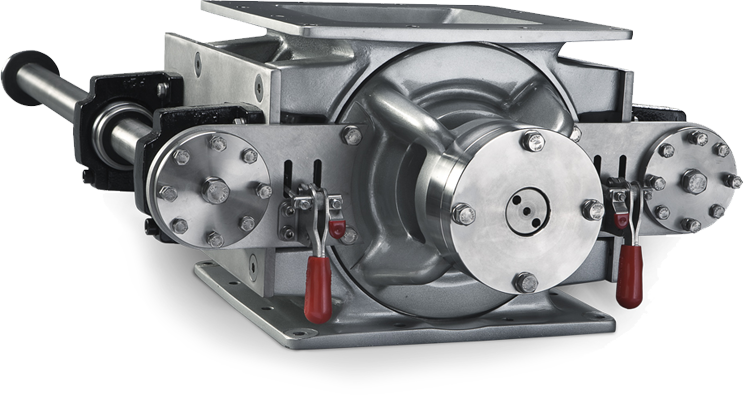

The ACS Valves Quick-Clean RotorRail™ helps accelerate cleaning. It also saves an average of $750 in lost productivity each time you have to clean the valve. Watch the video above and see how it works!

Longer lifecycles

For those who hate saying goodbyeWe don't want you to have to replace your valves with less than a year of production. The more longevity you get out of your valve, the less you pay over time to replace your valve or buy spare parts to keep your valve working longer and at an optimal rate.

NFPA and/or OSHA comes standard

There's no price on safetyACS includes NFPA and OSHA compliant features in all of our valves. Safety is never sold separately as something customers have to pay extra for—not all valve manufacturers have this as a guarantee.

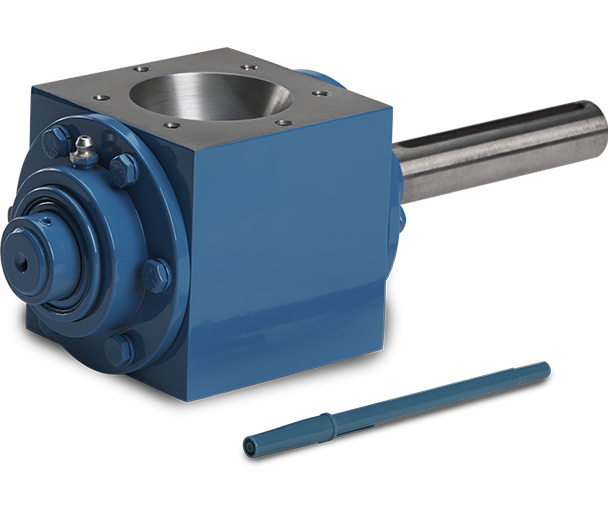

You can convey sticky material with a blow-through without having to spend money on replacing your parts from premature wear—and without reducing efficiency. Watch the video above to see how!

Added features to reduce risk of contamination

Don't get lystericalOur Run-Clean sanitary rotary valves include features that reduce material buildup, while also cutting cleaning time and costs. These features include protective coatings; polished, U-shaped rotor pockets; and sloped planes to increase material flow, reduce dead zones, and eliminate the bacteria or cross-contamination that could cost you a product recall.

Scalability

No cracking under pressureOur valves won't confine you to the industry-standard pressure rating of 7psi. With ACS valves, we can build in scalability to bring that pressure rating up, if and when you need it. This way, you can avoid the cost of purchasing a brand new valve every time you want to increase production.

Efficient processing can help your budget by saving you money on equipment and giving you a much higher ROI. The Channel Changer from ACS Valves can help keep your efficiency high. Check out why above!

Gained efficiencies

No more FOMOA quality valve not only means paying less in the long run; it means getting more. Improved energy efficiency. Increased productivity. More performance. And much more ROI.

Troubleshooting help

At your serviceDoesn't sound like a quality feature, but service means productivity. ACS Valves has a history in manufacturing entire pneumatic conveying systems, so if something goes awry, our system knowledge makes us way more helpful to you. You can't put a price on good service.

Plays well with others

Compatible with other brandsACS compatibility means that you can conveniently swap out valves built by other brands. Our rotary airlock and feeder valves can easily replace Prater Industries, Rotolok, Smoot, Meyer, DMN Westinghouse and Mac MD valves—among others.

ACS Valves Offer

- Reduced energy consumption

- Features for fast cleaning

- Metering consistency

- Design for effective material release and zero dead zones

- Coatings for reduced wear and longer lifecycle

- Shaft seals that don't have to be adjusted