Is your food manufacturing process safety-certified?

Farm to table food doesn’t necessarily mean safe food.

So what about farm to factory—to shipping container—to grocery store—to freezer—to table?

Suddenly food safety becomes much more of a priority, and much more difficult to regulate. Without the proper certifications, your buyers might not know whether they can trust your product.

That’s where the Global Food Safety Initiative (GFSI) comes in. A voluntary organization that was created by food manufacturers across the globe. It sets a standard for all other regulatory bodies to follow—globally—and lets your buyers know that your food is ready for the table.

Here’s a breakdown of what GFSI does, and some tips on how to keep your plant’s equipment compliant.

How does the GFSI work?

The GFSI delivers standards that buyers can count on without having to go through multiple auditing processes for each of the product industries that they are looking to sell.

Each industry has its own Scope of Recognition (scopes) set out by GFSI, from pre-process handling of plant products, to production of food packaging. They can be found here.

The standards are not regulated by any government body, and therefore can be used across the globe, while still keeping standards consistent and manageable.

There is, however, a separate category called Technical Equivalence which is dedicated to government-owned schemes. This compares government schemes to the existing technical requirements set out by GFSI in order to acknowledge their equivalence.

Can you get certified by GFSI?

You can’t get certified or accredited by GFSI.

Instead, they have a list of 13 GFSI-recognized schemes that have their own set of certifications.

These schemes are their own regulatory bodies whose standards have met the minimum food safety requirements set out by GFSI. The schemes must use third-party auditors to ensure that food manufacturers are consistently meeting the standards they set out.

Different schemes cover different scopes, but each scheme can cover more than one scope at a time. There are also some schemes that may only cover a single, specific scope.

You can find the schemes, along with which scope they go along with, here.

What do they look for in manufacturing equipment and facilities?

John Kukoly from GFSI-recognized scheme BRC Global Standards notes that the top three issues globally that they look out for in food safety all involve the potential of product recall.

The first being mislabeled foods that lead to macro-contamination in their products—things like unidentified allergens and the failure to record recipe changes.

The second is micro-contamination from pathogens in a certain product. And the third is physical contamination.

Physical contamination can come from the machinery itself, which is why it’s important to ensure you’re choosing the right type of equipment for your application.

“Given what it’s going to undergo, is it designed properly? Is it welded properly? Is the material proper so that it’s not going to corrode?” said Kukoly.

Best practices for preventing contamination

Using GFSI-recognized schemes can often be the first step in preventing contamination in your products. According to Kukoly many will provide the tools to help smaller businesses reach manageable goals in getting their plant certified.

When it comes to ensuring that your equipment is keeping your product safe, it comes down to design, materials of construction, and maintenance.

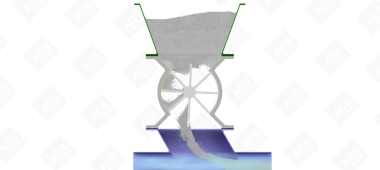

Some valves come with sanitary applications such as coatings, and easy-clean features that help prevent material build-up and reduce downtime. As a result, your machinery will mitigate cross-contamination and product recall.

Depending on your material, the wear on your valves will be different, meaning there will be variances in how often you have to replace parts or the equipment itself. This is something that should be built into your inspection and training programs.

Start by keeping records every three to six months. You will notice a pattern in your equipment wear and be able to better predict how often your equipment should be replaced—whether that’s every year, or every five years.

For more information on keeping your food safe, check out GFSI’s website here.

Categories: Safety , Sanitary

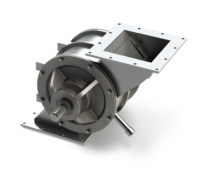

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

We have a series of items available for quick shipment

Items include: Pressure blower packages, MD Series, S-Pellet Series, Diverter Valves, Flex Tip Series, Screw Conveyors

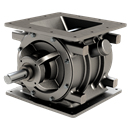

How to: Check rotor-to-housing tolerances

Keep your rotary airlock valve compliant with NFPA guidelines and maintain strong performance by checking your rotor-to-housing clearances regularly.

Newsletter

Stay informed on all things ACSWe’ll keep you up-to-date on the latest valve how-tos, handy tips, and news from ACS. It’s totally free and you can opt out at any time.