Experts

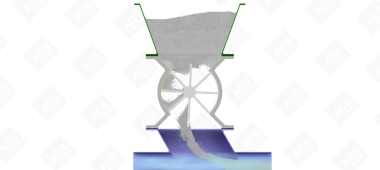

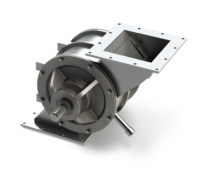

We design, engineer, and manufacture rotary valves for metering, feeding, and airlock in bulk material processing and pneumatic conveying applications. We stay up to date on industry regulations, as well as customer feedback, so we can apply new information into our designs.

All posts by ACSThere’s a certain amount of flow required to convey your materials consistently. And it’s the same type of flow that Alicia brings to the manufacturing of our own valves. She oversees everything from ordering to delivery, from start to finish, and makes sure that we stay reliable in our product quality and services.

All posts by AliciaBrittany heads up our sales team with more than 15 years in the bulk processing industry, which means she has some of the best all-around knowledge about rotary airlock valve configuration.

All posts by BrittanyWith special expertise in the mechanics of rotary airlock valves and pneumatic conveying systems, Greg is your go-to guy for any complex engineering questions.

All posts by GregThough she has a sparky personality, Megan’s knowledge of NFPA codes helps facilities like yours prevent fires and explosions. She can give you the best tips to keep workers safe.

All posts by MeganYour machinery can’t function if it’s missing a part, which is why the ACS team can’t function without our purchasing agent: Mike. He knows the ins-and-outs of the industry and ensures that your valves are made with the best materials out there. That way, ACS workers on the plant floor can get the job done right.

All posts by MikeWith her expertise in special coating applications, Nena can help you choose the right valve coatings to prevent material build-up, boost sanitation, and convey difficult products.

All posts by NenaIf you’re having trouble with a material jam, worn-out parts, or lost productivity, Paul is the one to call. He has 25 years of experience in manufacturing to help keep your equipment in ship shape.

All posts by PaulWhether you’re trying out new ingredients or need to make a switch, Terri’s material expertise can help you keep machinery clean and boost efficiency in your production process.

All posts by TerriWayne is our technical jet-setter. He will explore any possible explanation for why your mixer or valve might not be functioning at its best—even if he has to travel by planes, trains and motorcycles to get to your machinery. He’ll take a look at the minute details of your equipment to make sure that your whole system is back up and running in no time.

All posts by Wayne

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

We have a series of items available for quick shipment

Items include: Pressure blower packages, MD Series, S-Pellet Series, Diverter Valves, Flex Tip Series, Screw Conveyors

How to: Check rotor-to-housing tolerances

Keep your rotary airlock valve compliant with NFPA guidelines and maintain strong performance by checking your rotor-to-housing clearances regularly.